Supply Chain Initiatives

- Human Rights Initiatives

- Supply Chain Environmental Initiatives

- Partnerships with External Organizations

Supply Chain Management

Epson considers suppliers to be important partners in its business activities. As such, our procurement activities are designed to develop mutually beneficial trusting relationships with our business partners based on fairness, transparency, and respect.

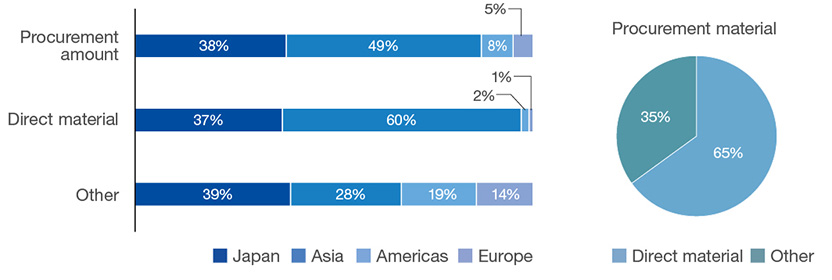

Epson procures goods from around the world. Domestic Japanese procurement accounts for about 38% of our total procurement spend. Asia accounts for the large majority of the remaining 62%.

Our procurement spend for direct materials (production materials and outsourced manufacturing) accounts for about 65% of the spend and indirect materials (including factory consumables, machinery, public relations, logistics, and staffing) for about 35%.

Epson has business with 1,700 direct material suppliers mainly in Asia where our main manufacturing sites are located, and about half of our indirect materials spend is in Japan.

Procurement Over View

Supplier Evaluation Program

Epson conducts multifaceted evaluations of all suppliers.

| Epson Group Supplier Evaluation Program | Evaluation Frequency |

|---|---|

| Indirect evaluation Evaluation using information from external credit reporting agencies Evaluation of credit score, business history, capital composition, business size, profit/loss, financing status, management, etc. |

Once per year |

| Direct evaluation (annual evaluation) Evaluation items: Quality control (Q), cost control (C), delivery date management (D), environmental management (E), management system including business continuity management (M), information security (S) |

Once per year |

| Detailed CSR evaluation Evaluation of compliance with the Epson Group Supplier Code of Conduct (RBA Code of Conduct) Evaluation of labor (human rights), health and safety, environment, ethics, and management systems |

Once per year |

| Evaluation of emergency response capabilities Self-assessment of ability to respond in the event of a natural disaster, fire, or other emergency. Evaluation of BCM system development, BCM delivery date management, BCM supply response |

Once per year |

| Safety management evaluation Self-assessment of response to fires and other emergency risks Evaluation of compliance with the Electricity Business Act, Fire Service Act, etc. |

Once per year |

Socially Responsible Procurement Program

Epson’s socially responsible procurement program is an annual cyclical activity. It consists of steps in which we ask suppliers to comply with Epson’s Supplier Guidelines and complete self-assessment questionnaires (SAQ). Epson then analyzes and evaluates risks, verifies the facts on-site or audits certain high-risk suppliers, and supports and works with suppliers on corrective actions.

Direct Evaluation (Annual Evaluation)

Epson generally evaluates all suppliers directly every year.

There are questions about quality (Q), cost (C), and delivery (D) as well as about the environment and management systems. In the management systems section, we check whether the company has put in place an effectively functioning business management and operational framework for managing risk and maintaining compliance. In addition, we now also evaluate information security due to the recent global increase in cyber attacks and information leaks.

If a supplier does not meet Epson's minimum standards in the annual direct evaluation, Epson asks them to correct deficiencies and provides them with support. If they do not improve within a certain period of time, Epson will decline to continue doing business with them. In 2024, one supplier did not meet Epson's minimum standards and was asked to take corrective action to address issues.

| Category | Number of questions |

|---|---|

| Q. Quality | 12 |

| C. Cost | 5 |

| D. Delivery | 5 |

| E. Environment | 5 |

| M. Management systems | 19 |

| S. Information security | 25 |

| Total | 71 |

Direct Evaluation Results

|

|

2022 | 2023 | 2024 | |

|---|---|---|---|---|

| Number of suppliers | 937 | 900 | 897 | |

| Number of sites | 1,582 | 1,425 | 1,435 | |

| % of suppliers who completed the self-assessment | Goal | 100% | 100% | 100% |

| Result | 100% | 100% | 100% | |

| Suppliers asked to take corrective action (number of sites) | 16 | 14 | 1 | |

Evaluation of Prospective New Suppliers

We require prospective new suppliers to agree to abide by the Epson Group Supplier Guidelines and the RBA Code of Conduct (with requirements covering human rights, health and safety, the environment, and ethics) as a condition for starting business with us. We also conduct indirect and direct evaluations* based on standards that set out supplier selection procedures.

* Self-assessments equivalent to the annual evaluations that are used to assess a supplier's quality control, cost control, delivery date control, environmental management, management systems, including business continuity management, and information security

Detailed CSR Evaluation

The detailed CSR evaluation is a part of Epson’s supplier CSR due diligence program. We are endeavoring to improve the level of CSR across our global supply chains. Toward this end, we have revised the scope, frequency, and some other aspects of our program to meet our obligations1 as a Regular Member of the Responsible Business Alliance (RBA).Every year, Epson evaluates supplier compliance with the Epson Supplier Code of Conduct (RBA Code of Conduct) based on a detailed self-assessment questionnaire (SAQ). Suppliers are asked to take corrective action, depending on the results of the SAQ. We also have a process for verifying supplier answers via audits, site observations, and interviews.

Suppliers can choose to answer either an online SAQ provided by the RBA or an SAQ prepared by Epson that is based on the RBA’s Validated Audit Program (VAP) audit criteria. The Epson SAQ is designed to thoroughly check the human rights situation at suppliers’ sites and thus has many questions in the labor section as well as questions about the protection of the rights of indigenous peoples and foreign immigrants. Epson’s SAQ form is available in multiple languages2 to ensure that local suppliers of Epson's overseas manufacturing sites understand the questions on the SAQ and provide accurate answers.

Suppliers who are deemed high risk are audited in accordance with RBA criteria and are asked to take corrective action as needed.

1 Summary of RBA Regular Member obligations

2 The SAQ for direct material suppliers is available in five languages and that for other suppliers is available in six languages.

Composition of Questions on the 2024 Epson SAQ

| Category | Scope & number of questions | |

|---|---|---|

| Direct material supplier |

Other suppliers |

|

| A. Labor (human rights) | 44 | 39 |

| B. Health and safety | 32 | 12 |

| C. Environment systems | 16 | - |

| D. Ethics | 14 | 8 |

| E. Management systems | 16 | 9 |

| O. Protection of the rights of indigenous peoples and foreign migrant workers | 5 | 5 |

| Total | 127 | 73 |

Epson SAQ Scores and Risk Ranks (FY2024)

| Risk rank | Score | Remarks |

|---|---|---|

| Low risk | More than 85 pts. |

|

| Medium risk | 65-85 pts. |

|

| High risk | Less than 65 pts. |

|

* The risk rank of suppliers who complete RBA's online SAQ is determined in accordance with RBA's risk ratings.

2024 SAQ

In 2024, we conducted a detailed CSR evaluation (SAQ and corrective actions) for the following major suppliers:

Scope of 2024 SAQ

| Selection Criteria | ||

|---|---|---|

| Direct materials | Major suppliers | Suppliers who account for 80% of the value of Epson's procurement spending1 |

| Other key suppliers | Key suppliers designated by each business line. Single source suppliers, etc. | |

| Other suppliers | On-site service vendors2 | Vendors on Seiko Epson and Epson Group manufacturing |

| Staffing and recruitment agencies | Operators that Seiko Epson and Epson Group manufacturing sites employ | |

| Logistics warehouse companies | Operators that Seiko Epson and Epson Group manufacturing sites employ | |

| Call center contractors | All call center service providers that the Epson group uses | |

1 Epson’s first-tier (direct) suppliers are arranged in descending order based on transaction amounts and selected until 80% of the total spend is reached.

If a first-tier supplier is a trading company, the manufacturer that supplies the trading company is asked to complete an SAQ.

2 Contractors who provide security, food service(canteen), and other services at Epson Group sites.

Direct material suppliers

We asked 267 first-tier direct material suppliers to complete the 2024 SAQ. All 547 manufacturing sites/ facilities responded. Other key suppliers, such as single-source suppliers, were also asked to complete the SAQ. In cases where the first-tier supplier was a trading company, we also asked the second-tier suppliers (the manufacturers) to complete the SAQ.

The number of suppliers using RBA-Online has been increasing each year and now accounts for about 36% of all Epson suppliers. For reference, the facility SAQ in RBA-Online has been updated and is now called the "Risk SAQ." It was optional in 2023 but was made mandatory starting in 2024.The changes to the SAQ tended to result in lower scores for the newly included Country Risk and Product Risk (business risk) questions in RBA-Online, with about half of the sites receiving a medium risk rating. The latest SAQ has new questions on Country Risk and Product Risk (business risk) . Scores in these areas tend to be lower, resulting in about half of facilities receiving a medium-risk rating. Epson communicated directly with suppliers that received a high-risk rating on RBA-Online or that failed to provide adequate answers, asking them to take corrective action.

All suppliers who completed the Epson SAQ were notified of their results. In addition to their SAQ scores, we prepared a feedback sheet that included advice on correcting identified issues. We also monitored the formulation and progress of the corrective action plans for addressing failures to comply with high-priority requirements related to human rights1 and provided assistance as needed.

No high-risk suppliers were identified in either the RBA-Online SAQ or Epson SAQ.

1 Representative high-priority requirements related to human rights:

・Prohibition of child labor (not detected)

・Prohibition of slave labor and forced labor (conclusion of appropriate employment contracts, freedom of movement, limits on company loans)

・Proper management of working hours (no more than six consecutive work days and a limit on working hours of 60 hours/week)

・Proper payment of wages (payment of at least the legal minimum wage and overtime, and timely payment of wages)

・Prohibition on charging workers recruitment fees

・Humane treatment (prohibition of harassment)

・Evacuation drills (enterprise-wide participation, with nighttime and dormitory drills, etc.)

・Provision of suitable personal protective equipment at no cost to workers

・Provision of safety measures for pregnant and nursing mothers, and provision of a clean room for expressing breast milk.

Evaluation Results for Direct Material Suppliers

| 2022 | 2023 | 2024 | ||||

|---|---|---|---|---|---|---|

| Number of suppliers evaluated | 1641 | 2701 | 267 1 | |||

| Epson SAQ (338 sites) |

RBA SAQ (111 sites) |

Epson SAQ (401 sites) |

RBA SAQ (146 sites) |

Epson SAQ (433 sites) |

RBA SAQ (243 sites) |

|

| Mid-term targets (KPI) |

|

|||||

| Low risk2 | 91% (407 sites) |

96% (524 sites) |

78% (530 sites) |

|||

| 91% (306 sites) |

91% (101 sites) |

94% (378 sites) |

100% (146 sites) |

60% (406 sites) |

18% (124 sites) |

|

| Medium risk 2 | 9% (42 sites) |

4% (23 sites) |

22% (146 sites) |

|||

| 9% (32 sites) |

9% (10 sites) |

6% (23 sites) |

0% (0 sites) |

4% (27 sites) |

18% (119 sites) |

|

| High risk 2 | 0% (0 sites) |

0% (0 sites) |

0% (0 sites) |

|||

1 Corporate group

2 Risk assessment criteria

| RBA-Online | Epson SAQ | |||

|---|---|---|---|---|

| Through 2023 | From 2024 | Through 2024 | From 2025 | |

| Low risk | > 85 pts | > 80 pts | > 85 pts | > 80 pts |

| Medium risk | 65-85 pts. | 60-80 pts. | 65-85 pts. | 60-80 pts. |

| High risk | < 65 pts. | < 60 pts. | 65-85 pts. | < 60 pts. |

Other suppliers

Epson is also working to ensure that its other suppliers, who are essential partners in its business operations, understand the RBA's requirements and are working to improve their operations in accordance with them.

Since 2019, we have been asking our major suppliers, including on-site outsourcing companies, temporary staffing and recruitment companies, and logistics warehouse companies, to complete the SAQ and take corrective action depending on the results. We exanded the scope of the SAQ in 2022 based on findings from a risk assessment.

At manufacturing sites, we conduct audits in addition to the SAQ to check the working environment and employment conditions of employees of companies stationed on the premises. We provide them with support until verifying the correction of issues that were identified, including issues involving long working hours, the granting of days off, consecutive working days, and appropriate payment of overtime wages. These efforts have helped to raise SAQ scores.

In 2024, we received completed SAQs from all 149 companies that have a permanent presence on Seiko Epson's business sites and major Epson Group manufacturing sites. We also received completed SAQs from all 102 temporary staffing and recruitment companies. Additionally, all 37 logistics and warehousing companies and all 27 call centers at sales companies also completed the SAQ. As with direct material suppliers, we ask these companies to create corrective action plans and correct any issues found in key areas related to human rights, and we confirm that the corrections have been completed.

Examples of confirmed corrective action

- Refunds to workers for expenses (for Japanese language education, visa acquisition, etc.) incurred in the sending country by foreign workers employed by contract manufacturing companies.

Other supplier evaluation results

| Supplier category | 2022 | 2023 | 2024 | |

|---|---|---|---|---|

| Completed SAQs | Completed SAQs | Completed SAQs | ||

| Staffing/recruitment agencies | 91 | 93 | 102 | |

| On-site service vendors | Security | 19 | 24 | 24 |

| Canteen | 13 | 16 | 18 | |

| Cleaning | 17 | 19 | 19 | |

| Facility maintenance | 17 | 17 | 16 | |

| Other Support | 67 | 75 | 72 | |

| (Sub-total) | (133) | (151) | (149) | |

| Logistics warehouse companies 1 | 8 | 8 | 572 | |

| Call centers1 | 15 | 25 | 27 | |

| Risk rank | Low risk (> 85 pts.) |

203 | 242 | 398 |

| 82% | 87% | 91% | ||

| Medium Risk (65-85 pts.) |

44 | 35 | 40 | |

| 18% | 13% | 9% | ||

| High risk (< 65 pts.) |

0 | 0 | 0 | |

| 0% | 0% | 0% | ||

1 As a result of risk assessment, SAQs were conducted on logistics warehouse companies and call center contractors in 2022, 2023, and 2024.

2 Includes 37 companies used by sales companies

Audits, on-site verification, and corrective action support

Epson schedules field audits and on-site verification of suppliers, mainly of Epson group's major manufacturing sites because it believes that it is important, as part of the detailed CSR evaluation due diligence process, to understand the situation. We provide assistance for corrective action taken by suppliers who are found to be at risk.

Third-Party Audits

The number of suppliers undergoing RBA (VAP) audits is increasing. The initial audit results revealed many issues in areas such as A Labor (human rights) and B Health and Safety. Epson is monitoring the progress of corrective actions through CAP (Corrective Action Plan) and closure audits, and is rolling these out as a means to strengthen Epson's supplier CSR efforts.

On-site verification and support for correction and improvement

Members of Epson's manufacturing sites visit suppliers to conduct on-site verification and support corrective actions.

For on-site service vendors, second-party audits were conducted by Epson employees, and they were asked to make improvements to the working environment, such as reducing and managing working hours, providing holidays, paying overtime wages appropriately, and prohibiting employees from having to bear expenses when they start working.

Audit and On-Site Verification (number of sites, Japan and other areas)

| 2022 | 2023 | 2024 | ||

|---|---|---|---|---|

|

Third-party audit [RBA (VAP) audit] |

Initial audit | 23 | 26 | 50 |

| Closure audit | 12 | 121 | 321 | |

| Second-party audit and on-site verification | Direct material suppliers | 216 | 217 | 231 |

| Other Suppliers (On-site service vendors, etc.) |

64 | 55 | 542 | |

| Total | 280 | 272 | 367 | |

1 Includes Priority Closure Audit

2 Includes 10 staffing and recruitment agencies.

Supply Chain Business Continuity Management

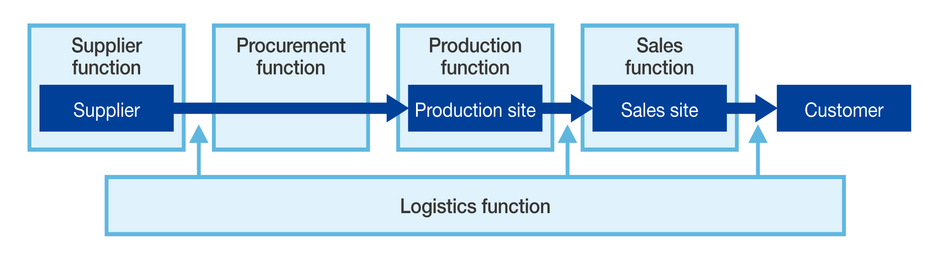

Epson drives business continuity management (BCM) programs across the supply chain so that it can resume supply within the target period and fulfill its supply responsibilities in the event of a disaster, accident, pandemic, or other contingency in the supply chain.

Related information: business continuity management

See herefor more information about Epson's business continuity management.

Business Continuity Management

Epson requires its suppliers to implement business continuity management (BCM) initiatives in the Epson Group Supplier Guidelines. Epson monitors the progress of suppliers' initiatives through regular evaluations, providing feedback on the results and supporting improvement activities as needed.

Safety management evaluation

Epson assesses the safety management of suppliers to verify compliance with relevant laws and regulations (such as the Fire Service Act). In fiscal 2024, Epson also added safety management assessments to the conditions for starting new transactions.

Supplier support through site safety inspections

To improve the effectiveness of its supplier safety management assessments, Epson has been sending safety management specialists to supplier sites since 2017 to conduct safety inspections and provide support for improving management.

Human Rights Initiatives

Epson has declared in its Human Rights Policy that human rights should be respected not only by Epson but also by its suppliers. As stated in the Human Rights Policy, Epson is committed to respecting internationally recognized human rights as stated in the Universal Declaration of Human Rights and the UN Guiding Principles on Business and Human Rights, and as a member and supporter of the RBA, we are committed to ensuring that our suppliers also comply with the RBA Code of Conduct. Through these efforts, we aim to ensure that human rights are respected throughout the entire supply chain of Epson products.

See here: Human Rights Due Diligence in the Supply Chain.

Supply Chain Environmental Initiatives

Epson is pursuing ambitious environmental initiatives under the Epson 25 Renewed corporate vision. We are looking to decarbonize and close the resource loop. We are also developing environmental technologies and providing products and services that reduce environmental impacts. Reducing the environmental impact early in the life cycle, at the procurement stage, is a particularly important issue, and one that Epson is addressing in cooperation with suppliers.

Environmental Requirements in the Supplier Guidelines

Epson's Supplier Guidelines include a code of conduct that suppliers are required to adhere to. In addition to requests related to quality, cost, delivery (QCD), and compliance, the Supplier Guidelines set forth the Supplier Code of Conduct on CSR (aligned with the RBA Code of Conduct). Regarding the reduction of environmental impact, Epson requires its suppliers not only to comply with the RBA Code of Conduct (covering pollution prevention and resource conservation, hazardous substances, solid waste, and air emissions, etc.) but also to address environmental issues such as reducing greenhouse gas emissions, promoting resource circulation, managing water resources, managing chemicals, and preserving biodiversity. Additionally, Epson requests that suppliers manage chemical substances contained in products and ensure compliance with environmental regulations at their factories.

Seeherefor more information about Epson's Supplier Guidelines.

Initiatives for Reducing Greenhouse Gas Emissions

Epson has established specific short- and long-term greenhouse gas (GHG) reduction targets, as well as a net-zero target for 2050, in line with the scientific target-setting methodology proposed by the Science Based Targets initiative (SBTi). These targets are based on the GHG emissions data for scopes 1, 2, and 3 that Epson has gathered in accordance with the GHG Protocol.

Also, an international initiative aiming for 100% electricity used in business activities to come from renewable energy sources by 2050 Joined the RE100 Epson Group offices around the world *1 Power used in the, 100% by 2023 As declared, with the goal of making it a renewable energy source Completed conversion to renewable electricity in December 2023 The company has done so. This will continuously reduce GHG emissions by approximately 400,000 tons per year.

In addition, Epson has joined the international initiative RE100. The company committed to achieving 100% renewable electricity at its sites worldwide1 by 2023.This transition was successfully completed in December 2023.This change will reduce Epson's GHG emissions by approximately 400,000 tonnes per year.

Going forward, we will work to reduce emissions throughout our supply chain in order to achieve our total emissions reduction target in line with the high target of the 1.5°C scenario.

*1Excluding some leased properties where the amount of electricity cannot be specified, such as sales offices.

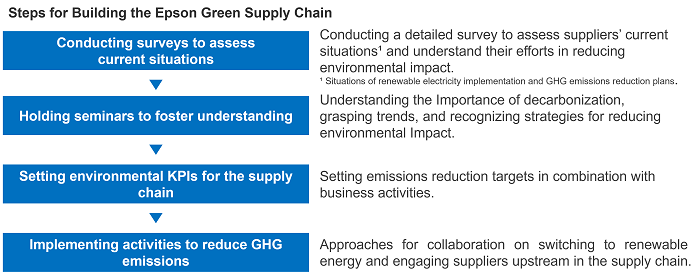

Epson Green Supply Chain

Epson's transition to renewable electricity in 2023 shows its significant first step in addressing the urgent global need for climate change action. However, a substantial portion of Epson's GHG emissions originates from its supply chain, necessitating strengthened collaboration between Epson and its suppliers to promote decarbonization across society.

Drawing on its experience and achievements in successfully completing the transition to renewable electricity early among manufacturers, Epson launched the Epson Green Supply Chain project in 2024. This project aims to foster understanding and encourage cooperation through workshops and seminars, while also implementing decarbonization target setting and providing support for the adoption of renewable electricity among suppliers. Through these activities, Epson seeks to increase the number of business partners who share its vision and to engage the entire supply chain in the challenge of reducing environmental impact.

Main Initiatives

Based on the results of interviews with major domestic and overseas suppliers that account for 80% of the value of Epson's procurement spending1, we are implementing initiatives appropriate to suppliers’ situations throughout FY2025. For example, we provide learning opportunities for suppliers that are about to begin, or are in the process of, calculating their Scope 1 and Scope 2 emissions, with a focus on deepening their understanding of the importance of supply chain–wide decarbonization and enabling them to acquire practical methods for calculating emissions.

| Implementation period | Description | For | |

|---|---|---|---|

| FY2024 | April | Procurement Policy Briefing for Business Partners | 221 companies |

| June | Epson Green Supply Chain Conference | 115 companies | |

| July | Decarbonization Seminar | 1,271 participants in total | |

| FY2025 | April | Procurement Policy Briefing for Business Partners | 218 companies |

| May | Introduction of an environmental survey system for GHG visualization using SaaS (Japan) | Approx. 250 companies | |

| August~ | Seminars (domestic and overseas) in accordance with supplier initiatives

|

Scheduled 18 times in total | |

| 2nd half~ | Started discussions with suppliers about joint procurement of renewable electricity. | Global | |

1 Epson’s first-tier (direct) suppliers are arranged in descending order based on transaction amounts and selected until 80% of the total spend is reached.

Strengthening Engagement to Reduce Environmental Impact

Epson uses supplier conferences and other opportunities to ask its suppliers for cooperation in reducing the environmental impact of business activities across its supply chains. We also periodically evaluate our suppliers' environmental programs and the results of their environmental impact mitigation efforts. We assist them as needed to improve.

Direct Evaluation (Annual Evaluations) and Detailed CSR Evaluations for Suppliers

Suppliers are asked to complete direct evaluations (annual evaluations) and detailed CSR evaluations that include questions about the environment. We collect and analyze their answers and provide feedback on the detailed CSR evaluations. Suppliers whose scores put them in the high-risk category are visited for on-site verification or audits and are aided to correct issues.

Environmental Impact Survey

In addition, we survey the suppliers who account for 80% of the value of Epson's procurement spending to find out about their policies and status on renewable electricity initiatives, use of recycled materials, water usage, and awareness of biodiversity, etc.

Response to Climate Risk

As part of activities to mitigate climate change, it is essential to promote the use of renewable electricity and supplier engagement. At the same time, it is urgent to address the physical risks posed by the increasingly visible effects of climate change. Epson has suppliers across Asia, including in Thailand, where severe floods are a regular occurrence, and in China, where there is high potential water risk. Epson recognizes that interrupted or delayed deliveries from suppliers due to floods and droughts, two typical climate risks, could seriously impact the manufacture and sale of Epson products and need to be addressed to avoid inconveniencing customers.

Biodiversity Conservation Initiatives and TNFD Recommendations

Epson believes that preserving healthy biodiversity is essential to sustaining both our business activities and the lives of our employees. We are steadily addressing factors that threaten biodiversity—such as climate change and pollution—through initiatives that include climate action, resource conservation and recycling, and the prevention and management of pollution and chemical substances.

We will continue to organize and disclose our activities, in line with the Taskforce on Nature-related Financial Disclosures (TNFD). Through these efforts, we aim to minimize our impact on nature and biodiversity, foster greater harmony with local ecosystems, and contribute to the realization of a sustainable society.

Related information: Response to TNFD recommendations

Click here to learn more about Epson's environmental activities

Related Information: Epson's Environmental Activities

Partnerships with External Organizations

In addition to our own initiatives, Epson supports and actively participates in alliance activities in order to resolve CSR issues, including human rights issues in the supply chain. We have joined the RBA and JEITA to work on solving societal issues around the world and improving supply chain CSR through industry collaboration.

Global initiatives

Responsible Business Alliance(RBA)Regular member

Number of member companies: 266 (as of 6/2025 )

Domestic Japanese industry initiative

The Japan Electronics and Information Technology Industries Association (JEITA),CSR Committee

Member companies: 30 (as of 6/2025)

Example activities:

- General CSR support (e.g., tracking and sharing information on regulations in various countries)

- Streamlining of socially responsible procurement (e.g., develop guidance on responsible corporate conduct, educate and build awareness in the supply chain)

- Utilization and development of grievance mechanisms

- Correspondence with government and CSR-related organizations and institutions