Occupational Health and Safety

- Approach to Occupational Health and Safety

- Safety Management Initiatives

- Fire and Natural Disaster Safety

- Facility Safety Maintenance

Approach to Occupational Health and Safety

We at Epson make health, safety, and security the highest priority in corporate management. We believe that maintaining a healthy and safe work environment, as well as promoting physical and mental wellbeing, are essential for a healthy company. We have therefore created occupational health and safety programs at all Epson facilities around the globe to ensure that all workers in the Epson Group can enjoy work in the knowledge that they are safe.

Epson has established a Basic Occupational Health and Safety Policy that is founded on the four pillars of safety, health, fire and disaster management, and facilities, and we make officers, employees, and our partners aware of our occupational health and safety (OH&S) activities.

Epson Group Basic Occupational Health and Safety Policy

Epson is evolving the Group's OH&S activities to align them with ISO 45001, thereby further improving the workplace health and safety environment. Bearing in mind that safety, security, and health are our top priority, we will comply with all applicable local and international laws and regulations as well as with company rules. We will strive to maintain and promote both mental and physical health. Together, we will work as one to achieve our goals of zero serious occupational accidents and industrial incidents and zero occupational illnesses, thereby laying the foundation for achieving sustainability and enriching communities.

Yoshihiko Kubota

Overall Health and Safety Controller

Deputy General Manager, Human Capital and health and productivity management Division

Occupational accident situation

In FY2024, we did not have a serious occupational accident *1. serious occupational accident We keep track of the number of high-risk machines that could directly cause a serious occupational accident, and we regularly assess how these risks are being managed. The number of occupational accidents resulting from a reaction to motion or over-exertion decreased from 10 to six. Although not considered serious, these accidents resulted in time off. However, the number of incidents involving falls, cuts, and collisions (both hitting and being hit) have either stayed the same or increased. Caught-between accidents jumped from zero in FY2023 to six.

OH&S activities were expanded to cover sales companies. This has led to a decrease in the number of occupational accidents, particularly back injuries in warehouse work and falls in office settings. On the other hand, occupational accidents in manufacturing, such as caught-between accidents, cuts, and leaks, are increasing. We are strengthening the review and improvement of non-routine tasks, such as equipment maintenance, which rely heavily on specialists.

There were four incidents involving smoke and fire. In addition to the enhanced inspection of home appliances that began in FY2024, we will be strengthening the management of highly flammable chemicals.

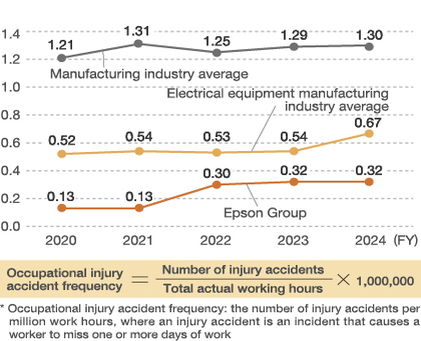

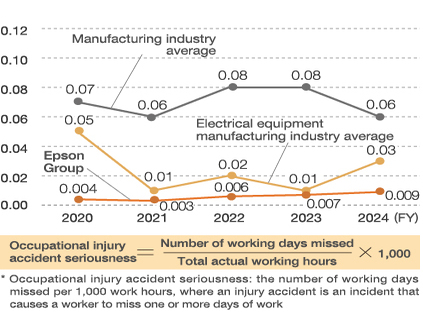

The occupational accident frequency and severity *2 increased slightly from last year, but they remain below the national average.

*1 Accidents involving death, disability, or other comparable aftereffects

*2 Indicator of occupational accidents, calculated according to the formula of the Ministry of Health, Labor and Welfare.

*2 Occupational accident indicators that are calculated in accordance with a formula of the Ministry of Health, Labour and Welfare

Occupational Accident Frequency Rate Trend Occupational Accident Severity Rate Trend

Workdays lost are calculated based on the criteria below.

・Fatality: 7,500 days

・Permanent total disability: 7,500 days for physical disability levels 1 to 3

・Permanent partial disability: 50 to 5,500 days depending on disabilitylevels 4 to 14

・Temporary disability: The total number of lost days, including designated holidays, is multiplied by 300/365

Number of occupational accidents by type in FY2024

(Unit: Accident)

| Falls | Reaction to motion,

over-exertion |

Caught-between | Leaks, spills | Cuts, scrapes | Fire & smoke | Collisions | Other Support | Total |

|---|---|---|---|---|---|---|---|---|

| 25 | 6 | 6 | 5 | 4 | 4 | 4 | 5 | 59 |

* The count only includes accidents that resulted in the loss of one or more workdays or secondary evacuation.

Safety Management Activities

The table below shows the targets for FY2024. After reviewing the results from FY2024, we set new targets for FY2025, as shown below.

| METRIC | FY2024 Target | FY2024 Result | FY2025 Target |

|---|---|---|---|

| Serious occupational accidents & industrial incidents | Zero | Zero | Zero |

| Occupational accident frequency rate | ≤ 0.30 | 0.32 | ≤ 0.32 |

| Occupational accident severity rate | ≤ 0.006 | 0.009 | ≤ 0.009 |

Actions for FY2025

Based on an analysis of occupational accidents that occurred in FY2024, we will focus on the activities below in FY2025 to prevent the same or similar accidents from recurring and preemptively avoid other accidents.

- Falls: In addition to making environmental improvements to staircases and eliminating trip hazards, etc., we will try to eliminate falls by helping employees to improve or maintain their physical fitness. Eliminate falls by focusing on the physical fitness and awareness but also by alerting individuals to common personal risk factors.

- Non-routine work: Review risks and create company-wide work standards to prevent cuts, caught-between accidents, and leaks/spills that occur during infrequent tasks such as equipment maintenance.

- Fire and smoke: Strengthening fire prevention, including by regularly inspecting home appliances and reviewing their specifications (conducting safety assessments) and by implementing electrostatic discharge measures where flammable substances are stored.

When introducing new machinery or equipment, including during the research and development stage, we identify and assess risks in accordance with the Group's risk assessment criteria. We then implement safety measures based on the findings.

ISO 45001 certification acquisition situation

In order to protect employees from occupational health and safety risks, Epson has been working on a three-year plan to acquire ISO 45001 certification, the international standard for occupational health and safety management systems, at all of its manufacturing sites in Japan and overseas (28 sites in total). In fiscal 2024, the final year of the plan, two new domestic sites obtained certification, completing the acquisition of certification at all manufacturing sites as originally planned.

Global sharing of OH&S activities information

Epson production sites in Japan and abroad regularly hold meetings between management and operational staff and between labor and management to share information and level up their OH&S activities.

At the management level, the senior executives and Epson Group company presidents who head up health and safety programs at Epson sites in Japan gather twice a year for a general health & safety controllers’ meeting in which the director in charge participates. The same thing happens separately overseas. These meetings are used to discuss the current situation and challenges faced in occupational health and safety and to work on improvements.

At the labor-management level, members of the labor union and management convene monthly health and safety committee meetings to gather ideas and feedback from workers that can be used to improve site health and safety.

For our overseas sales companies, which began OH&S activities later than our production sites, we are working to raise overall standards through tailored support. In addition to holding general meetings, we also conduct site-specific meetings to share location-specific challenges and successful examples from other sites.

General health and safety controllers’ meeting with overseas sites

Building awareness internally through Safety News bulletins

Epson analyzes all occupational accidents and industrial incidents in the Epson Group, identifies causes, and implements measures to prevent similar incidents. Information on occupational accidents and industrial incidents—including causes, countermeasures, and recurrence prevention measures—is compiled into "Safety News” bulletins and disseminated to all employees through the company intranet.

Human resource development through health and safety education

Epson considers its comprehensive health and safety education courses to be among the most important in its education program. A key feature of the program is that the curriculum is tailored to the different echelons and roles of employees.

For general employees, we focus on practical training in things such as risk assessment and hazard prediction. For management and supervisory staff, the emphasis is on acquiring skills to lead the workplace, while, for specialists, the focus is on improving practical skills. This approach is integrated into the company-wide education curriculum.

In FY2024, approximately 80,000 people received education related to occupational health and safety. This includes 28,451 general employees in Japan, 48,003 general employees overseas, 3,187 managers and supervisors, and 2,025 specialists (e.g., safety officers and chemical substance managers).

Fire and Natural Disaster Safety

Epson has in place a Group-wide plan to control priority risks. We regularly review and update the plan and conduct drills based on it to prepare for fires, earthquakes, and wind and flood damage. These disaster drills are designed to preserve life, minimize damage, and enable a recovery. We test their effectiveness and take steps to further improve them.

Initial disaster response

In the event of a disaster or the threat of a disaster, a Disaster Prevention Headquarters will be established, led by each Group site in Japan and overseas, to direct disaster countermeasures and measures. When established, the headquarters will immediately report to the secretariat of the Seiko Epson General Disaster Countermeasures Headquarters as the first report. The matters to be reported at that time are stipulated below.

- personnel safety

- damage to buildings, equipment, and facilities

- impact on operations

- any other information that the disaster task force chief deems necessary

To gather information about disaster situations and to ensure that information is transmitted even if infrastructure is disrupted, we have set up multiple channels to receive reports from both domestic and international sources. Our domestic sites have put in place a system that enables us to verify the safety of our people and to provide information not only at the Group-wide level but also at the local site level. Authority has been granted to Epson sites to use our emergency communication system to gather information on employee safety and to share that information with local authorities. Our overseas sites also ask employees to report their situation when there is a natural disaster. Until last year, only our manufacturing sites were do so. However, starting this fiscal year, our sales sites have also begun to received reports from their employees so that we are now able verify the safety of all Epson Group employees worldwide.

The Central Disaster Task Force administrative office reviews site reports and sets up a central disaster task force if the damage is extensive or wide-spread or if an affected site asks it to do so. The central disaster task force assesses the situation at each site, issues comprehensive guidance to each disaster task force, and provides prompt support and actions for a recovery. It also compiles recovery prospects and announces them both internally and externally. Once the disaster task forces have completed their initial response, a swift transition to the business continuity plan (BCP) is made.

Disaster preparedness

Many Epson sites in Japan and abroad have their own fire brigades. They regularly conduct drills to prepare them to take the lead in providing aid and minimizing damage to facilities and equipment in the event of a fire. Moreover, all employees at our domestic sites undergo training in the use of fire extinguishers to prepare them to fight fires in the incipient phase.

Each site also prepares for other disasters by identifying risks based on local hazard maps and developing drill plans accordingly. All employees participate in drills in which they evacuate buildings or extinguish fires in accordance with a simulated workplace disaster scenario.

In terms of organizational structure, we have put in place initial response guidelines for the entire Epson Group. These guidelines are regularly reviewed and updated, and Group sites integrate these guidelines into their own processes to establish a system that works best for them.

Preparations in response to emerging infectious disease

Facility Safety Maintenance

Epson maintains safe facilities in line with the Epson Group Basic Occupational Health and Safety Policy to prevent accidents caused by faulty buildings, equipment, and facilities.

Facility safety maintenance covers all domestic and foreign Epson Group buildings and building equipment, including but not limited to electrical equipment, air conditioning and sanitary equipment, drainage equipment, disaster management equipment, communication equipment, and equipment for supplying gas and chemicals to production machinery. Maintaining the soundness of buildings and building equipment, planning and maintaining them to minimize damage from fires and earthquakes, and ensuring the safety of employees and others will help Epson to ensure business continuity and deliver products and services on time. Epson thus has in place a variety of facility safety measures.

For example, before a new building or new building equipment is constructed, installed, refurbished, or removed, a safety assessment is conducted to identify potential problems and improve designs. In addition to managing safety during construction, we also conduct safety assessments prior to use to verify that buildings and building equipment were constructed or installed as designed. If there is a problem, we have it fixed, and if it is not fixed, the building or equipment cannot be used until the problem is resolved.

In addition to ensuring compliance with applicable laws, regulations, and codes when conducting safety assessments, we are also working to build safer buildings and building equipment by establishing our own standards and preventing the recurrence of past accidents and problems.

In many cases, we enlist the cooperation of outside partners to do the actual construction work. When we hire a partner, we carefully manage safety by communicating the construction rules, controlling access to the site, ensuring that confidentiality is maintained, and providing instructions for working safely. We also try to raise safety awareness among our partners by holding safety conferences.

To encourage employees to acquire the licenses and qualifications needed for facility management and to maintain and raise the level of facility management, Epson provides employees with ongoing professional education. To help ensure electrical safety, Epson created its own program for training and qualifying electrical equipment technicians. Only qualified technicians are allowed to perform electrical work and maintenance on machinery used at Epson sites worldwide.

We at Epson will continue to try to eliminate occupational accidents through activities like these.