Human Resource Development

Approach

To execute our business strategies and achieve our plans, we need to embed purpose and the Epson Way throughout the workforce. We need people who understand and embrace the strategic goals set forth in the corporate vision. We need people who have a broad perspective, professional expertise, and the ability to quickly adapt to change. We need people with a customer perspective who can take initiative and autonomously create customer value.

Epson wants its people to shape their own careers and continue to grow over the long term. To this end, we provide on-the-job training (OJT) and, on top of that, specialized training and education tailored for different echelons. We also provide opportunities for challenges, such as reskilling, rotation, and internal recruitment, so that employees can better respond to changes in the internal and external environments. In addition, we are working to develop human resources who can play an active role globally in order to put us in the best position for success from a global perspective.

Human Resource Development Initiatives

Training for Career Development and Growth

Epson aims to be a company where people can develop their careers autonomously and continue to grow over a long-term time horizon.

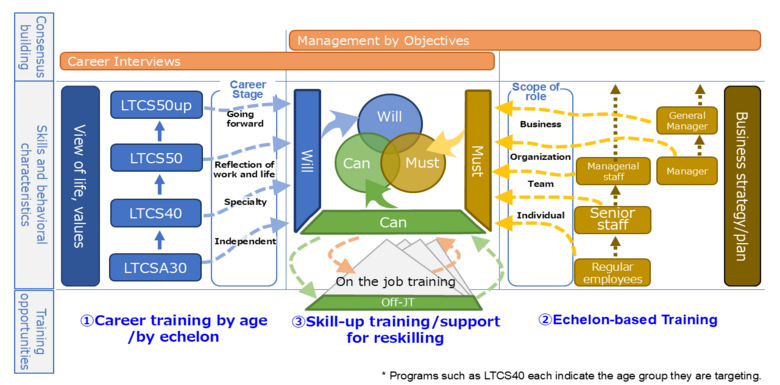

To support the career development and growth of each employee, we have created a training system concept using the "Will, Can, Must" framework. It consists of three major training categories: (1) age- and rank-based career training, (2) echelon-based training, and (3) skills training and reskilling support. By linking training and systems to "Will, Can, and Must" respectively, we aim to enhance the effectiveness of learning

and increase employee satisfaction and motivation for growth.

(1) Career Training by Age and Level

Epson is continually working to create an organization where people can grow, and we support employees in building careers that give them a sense of accomplishment and growth.

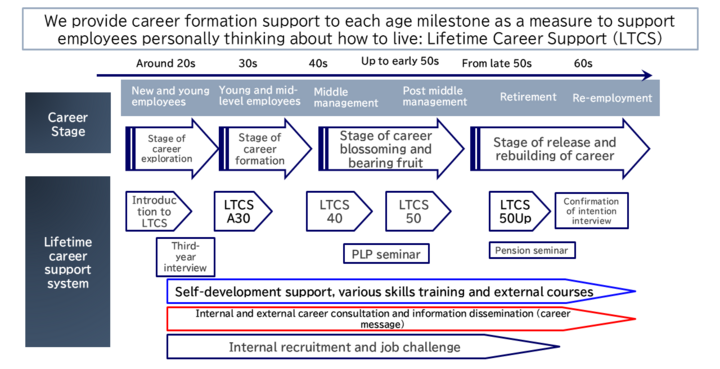

In addition to developing the skills to quickly respond to shifts in business strategies and changes in the environment, we also provide "Lifetime Career Support Training" (LTCS) tailored to each age group and rank at each age milestone, so that employees can think about the career they want to pursue from a medium- to long-term perspective and take the initiative to work towards achieving that goal.

●Fiscal 2024 results

LTCS50UP training (for company-wide aged 55): 381 people (total of 773 people by fiscal 2024)

LTCS50 training (for company-wide aged 50): 325 people (3,197 people by fiscal 2024)

LTCS40 training (for company-wide aged 40): 175 people (2,041 people by fiscal 2024)

LTCSA30 training (for employees around 30 years old): 159 people (196 people by fiscal 2024)

LTCS introductory course (conducted as part of new employee training) 377 people

Interviews with Third-year Employees

The Human Resources Department interviews young employees who joined the company right out of school and are in their third year with the company to help them quickly improve their effectiveness and to encourage retention. The goal is to enhance the engagement of individuals with their work and workplace by listening to their concerns regarding their job, work environment, and personal career development, and by providing support, including within the workplace.

(2) Echelon-based Training

Managers and Leaders

Supervisor management and communication in the workplace play an extremely important role in ensuring that employees thrive and grow.

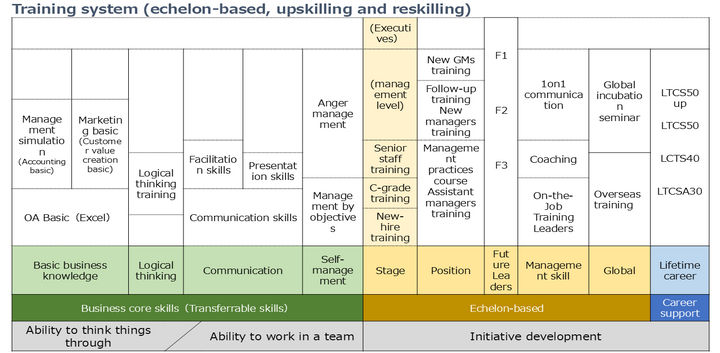

For managers, we provide a variety of content to learn management skills through training for new managers, department managers, and 1 on 1 communication training, as well as through partnerships with external organizations.

Before being appointed to a managerial position, employees are required to take a "Management practices course" to understand the roles and acquire the requirements of the "business axis" and "behavioral axis" required for managerial positions.

The "Business Axis" is training in skills to correctly understand the objectives of management strategies and respond quickly, flexibly, and appropriately to changes in the internal and external environment, while the "Behavioral Axis" is training in skills to develop and support the growth of team members by deploying the roles to be played by organizations and individuals to realize strategies and assigning the right personnel.

We also offer F1, F2, and F3 training as selective training programs.

In F1 training, candidates for the next board of directors learn skills to become managers with other candidates at the same level. F2 training is for general managers and section managers to acquire practical skills to become the next generation of business managers, and F3 training is a practical training program in which participants learn the basics of business and actually make business proposals. Through these programs, the next generation of leaders, including those of group companies, are being developed.

New Employees

Epson positions the first year of employment as a period of training for new employees to acquire a basic attitude toward work and how to perform their work.

During the first three weeks after joining Epson, group training is provided to new employees at Epson Group companies in Japan to help them acquire the following

Understand and practice the behavior expected of Epson employees.

∙ To learn the attitude and mindset of manufacturing, which is the foundation of "saving, small, and precise technology.

To realize the importance of working together as a team.

Training ranges from lectures on the Epson Global Code of Conduct to hands-on training in manufacturing. New employees learn the importance and enjoyment of working in teams, through group activities that take place throughout the training period.

After they complete group training, new employees are sent to the department where they have been assigned. There they learn their job through on-the-job training under a mentor. Mentors are usually selected from among young employees with three to five years of experience. They produce training plans tailored to the individuals they will be mentoring and, for a full year, provide them with the support they will need to stand on their own. Mentors themselves are expected to grow through this experience.

At the end of the first year, the new employees gather again for follow-up group training, where they can observe how they and others have grown and developed. To further solidify the foundation they have built as a business professional, they review the previous year and consider action plans for the next year and beyond to achieve further growth and expand their contributions to the company.

(3) Skills Training and Reskilling Support

Our reskilling efforts are designed to support employees' desire to continue to grow and develop their careers autonomously, as well as to enhance their skills and strengthen their ability to respond to change.

Based on the acquisition of business core skills such as basic OA skills, logical thinking, and dialogue skills, we offer a wide range of specialized training programs tailored to the job and position.

We also support skill development through individual self-development by providing external training sites and subsidizing qualification acquisition and correspondence courses.

Trainning System

Overseas Dispatch of Young Employees

Epson operates globally, with R&D, production, and sales sites around the world. More than 80% of our revenue and 70% of our employees are overseas. We send young employees to live and work at our overseas affiliates to gain work experience and develop cross-cultural competence, so that they can be active on the global stage in the future. (Overseas Trainee System)

Although the program was temporarily suspended due to COVID-19, it resumed in FY2022 for the first time in three years, and 27 employees were dispatched in FY23 and 26 in FY2024.

Number of Employees Assigned to Overseas Training Programs

| FY2017 | FY2018 | FY2019 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|---|

| Number of people | 28 | 22 | 13 | 1 | 27 | 26 |

Rotation and Internal Recruitment

Epson emphasizes job rotation as a way to broaden the range of skills, experience, and knowledge of employees so that they can continue to grow and shape their own careers, better adapt to internal and external environmental changes, and contribute to the effective and efficient operation of the value chain. We have set a rotation rate target of 15% or more. Rotations have been made a requirement for promotion and an objective in management evaluations. We are also systematizing training for personnel moving into new roles.

In addition, we have positioned the internal recruitment system as an important means of developing human resources who are willing to take on new challenges, broaden their perspectives, and enhance their skills by experiencing a wide range of work and workplaces.

Rotation Rate

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | Target | |

|---|---|---|---|---|---|---|

| Rotation Rate | 7.3% | 9.0% | 10.0% | 10.1% | 10.1% | 15% or more each fiscal year |

Internal Recruitment Results

| FY2020 | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Number of applicants | 148 | 378 | 293 | 325 | 236 |

| Number of transferees using this system | 12 | 217 | 201 | 176 | 133 |

Management by Objectives

Epson has used a management by objectives system for more than 30 years. All employees are subject to the system. Managers and their subordinates work together to set objectives on which they can both agree. Progress toward the objectives is periodically reviewed, end results are evaluated, and new, higher objectives are set. The management by objectives system is itself an on-the-job human resource training system. It is a win-win development cycle in which individual growth leads to the growth of the organization and the company.

Creating Value That Exceeds Customer Expectations and the Monozukuri Juku

Epson's Monozukuri Juku, or Manufacturing School, aims to enhance the customer value we create. To this end, we teach our personnel basic technology and skills and have them experience monozukuri (the art and science of manufacturing) by performing specific manufacturing tasks step by step. This helps them tackle jobs from different angles. To give a specific example, employees learn the basics of component processing technology (molding and pressing). Once they learn these, employees have the skills to make the various parts that go into a product. Employees also learn by mastering essential skills for making production lines more efficient (e.g., automating lines or operating them with fewer staff).

In addition, we contribute to the community and society by giving practical training for new employees of local businesses, offering corporate experiences to junior and senior high school students, and providing instruction for technical skill trainings. We also send experts abroad to take part in official development assistance for building technical skill evaluation systems at the request of the Japanese Ministry of Health, Labour and Welfare.

Developing Human Resources to Support Company-wide Production Strategies

In recent years, the manufacturing industry has been facing serious supply and logistics risks due to uncertain factors such as geopolitical risks, natural disasters, and pandemics, in addition to global wage increases and human resource shortages. It is becoming increasingly difficult to respond flexibly to these rapid changes in the environment with a production system based on abundant labor and concentrated production in specific regions, as has been the case in the past. In light of this situation, Epson has set forth in "Epson 25 Renewed" the promotion of smart factories through automation and digitalization, as well as the strengthening of decentralized production and near-consumption area production.

In order to realize such flexible, efficient, and global manufacturing, it is important to develop engineers who support the manufacturing value chain. Monozukuri Juku At MHI, we hold more than 300 training sessions a year to foster engineers in a variety of fields, including mechanical drafting and measurement necessary for equipment manufacturing, as well as training to acquire machining skills.

In addition, to foster engineers who will promote automation, we have established a curriculum that includes "basic mechatronics training" to learn elemental technologies such as pneumatic and electrical control and the basics of equipment assembly and adjustment, as well as "FA robot training," "image processing training," and "practical mechatronics training" to acquire more practical technologies and skills, We provide our employees with opportunities to learn.

In addition to training engineers in Japan, we are also developing manufacturing and machine maintenance leaders at our overseas manufacturing sites overseas affiliate based on the domestic training program. In addition to local training, we also utilize a remote training system established for periods when overseas business trips are difficult, to provide necessary training in a timely manner. Through these efforts, we are promoting optimal human resource development and improving the level of process management at each of our overseas subsidiaries so that they can respond to company-wide production strategies such as decentralized production.

Developing Young Technicians through National Skills Competitions

Epson, a manufacturing company, utilizes Technical Olympics training to develop "sharp technicians"1 who have acquired the knowledge and skills necessary for manufacturing at an early stage. Trainees are allowed to compete in the WorldSkills competition up to two consecutive times starting in their second year with the company, with the aim of acquiring national-level skills through short-term, intensive training. The seven categories of competition are "precision equipment assembly," "plastic molds," "mechatronics," "electronics assembly," "autonomous mobile robots," "web design," and "watch repair," all of which can be applied to real work.

New employees assigned to Monozukuri Juku as WorldSkills trainees experience the basics of "manufacturing" through sanding and sawblade cutting, and learn basic mechanical and electrical knowledge for each job category. In addition to the daily job-specific training, reinforcement training is held three times a year to strengthen physical fitness and set goals to foster a sense of solidarity as a team.

In addition, in anticipation of the national competition, we hold joint training sessions with other companies participating in the WorldSkills competition and actively promote the acquisition of national qualifications such as machining technician, electronic device assembly technician, web design technician, and watch repair technician. After completing the WorldSkills training, the trainees are assigned to the business department, where they undergo applied training to shift from the basic skills developed in the WorldSkills training to skills for product manufacturing. The recipients have been highly praised for their activities that exceeded their expectations.

*1Skilled workers with the ability to break through precedents and create innovative technologies and systems

FY2024 Training Data

Main Online Courses (Japan)

| Course Name | Course Takers |

|---|---|

| e-International Trade Control for all employees (2024) | 19,055 |

| e-Environmental Basic Education 2024 | 20,988 |

| e-Epson Compliance (2024) | 20,971 |

| e-Information Security Basics (2024) | 21,249 |

| e-Procurement Basics_Procurement Compliance Law (2024) | 18,365 |

| e-Harassment Prevention Education (2024) | 20,834 |

| e-Occupational Health and Safety Training (2024) | 18,416 |

*Number of participants by the end of March 2025 (Seiko Epson Corporation and domestic affiliates)

Training by Echelon

| Course Name | Who | Course Takers | Percent |

|---|---|---|---|

| New employee orientation | New hires | 373 | 100% |

| C-level employee training | New C-level staff | 356 people | 98.0% |

| Senior staff training | New senior staff | 279 people | 93.6% |

| Section manager training | New section managers | 135 persons | 89.0% |

| General manager training | New general managers | 42 people | 93.3% |

* Data for participation in training courses by echelon at Seiko Epson Corporation are current as of March 31, 2025.

* Those who have not yet taken the training are scheduled to take it in FY2025

* SSF is senior staff (team leader level, not position)

Training Hours

| Unit | FY2021 | FY2022 | FY2023 | FY2024 | |

|---|---|---|---|---|---|

| Training by regular employee | Hours | 20.9 | 21.5 | 34.2 | 27.7 |

| Total training hours | Hours | 228,696 | 235,910 | 375,219 | 321,351 |

* Hours spent by Seiko Epson Corporation regular employees in group training and in taking online courses

Financial Assistance Provided in FY2024

| Financial Assistance for | Cases |

|---|---|

| Acquisition of self-development qualifications | 309 cases |

| Self-development correspondence courses | 256 cases |

| Acquisition of work-related qualifications (fully subsidized) | 581 cases |

(All numbers are total numbers)