Responsible Mineral Sourcing

Responsible Minerals Sourcing Policy and Principles

It is known that there are cases where profits from the extraction and sale of minerals such as tin, tantalum, tungsten, and gold (3TG) in conflict-affected areas such as the Democratic Republic of the Congo (DRC) and neighboring countries are used as a source of funding for armed groups and anti-government forces carrying out atrocities and human rights abuses. Furthermore, it has been pointed out that cobalt mines in the southern part of the DRC have become breeding grounds for child labor. Mineral mining and trade carry social and environmental risks.

It is Epson's corporate policy to avoid engaging in any form of human rights violations or environmental destruction. Epson does not tolerate human rights abuses in the procurement of minerals used in Epson products. We will not engage in business relationships with any party involved in human rights abuses, nor will we support operations that result in the degradation of social, economic and environmental conditions.

Based on management's recognition that responsible mineral sourcing is a social issue that needs to be resolved, Epson has incorporated initiatives for "responsible mineral sourcing" into the Principles of Corporate Behavior and designated it as a key theme under the materiality category of "Fulfilling Social Responsibility." Additionally, we support the missions and initiatives of the Responsible Business Alliance (RBA) and the Responsible Minerals Initiative (RMI), and are a member of the organizations.

As mentioned above, we will work towards realizing responsible minerals sourcing by establishing a system for responsible minerals sourcing, participating in initiatives, and obtaining the cooperation of our suppliers.

Responsible Minerals Sourcing Initiatives

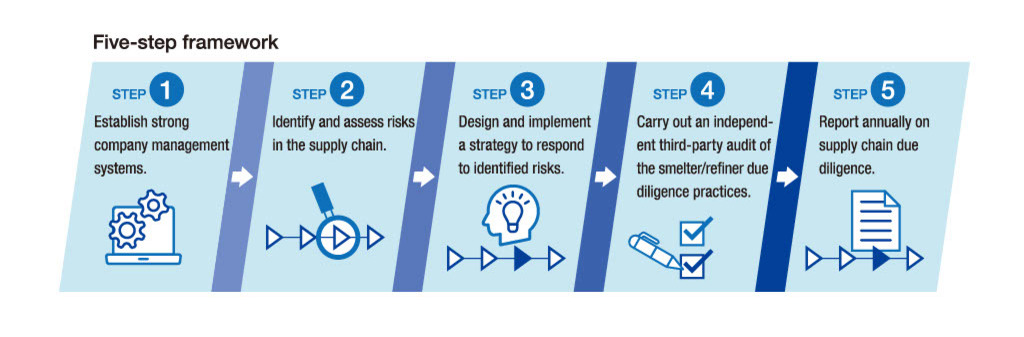

To responsibly source minerals used in Epson products, our program follows a five-step framework according to the Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas issued by the Organization for Economic Co-operation and Development (OECD).

The five-step framework and Epson's initiatives

STEP 1: Establish strong company management systems.

Epson establishes a Group-wide policy, implements a supply chain due diligence program, concludes written agreements with suppliers, and establishes a grievance mechanism.

STEP 2: Identify and assess risks in the supply chain.

Epson identifies and assesses risks in our supply chain by conducting surveys.

STEP 3: Design and implement a strategy to respond to identified risks.

Epson reports the results of risk assessments to the Chief Procurement Officer, discusses risk mitigation plans with tier 1 suppliers, and monitors their performance.

STEP 4: Carry out an independent third-party audit of the smelter/refiner due diligence practices.

Epson uses the results of RMI's Responsible Minerals Assurance Program (RMAP) in assessments.

STEP 5: Report annually on supply chain due diligence.

Epson discloses its due diligence status on the company’s official Web site, in the annual integrated report, and in other media formats.

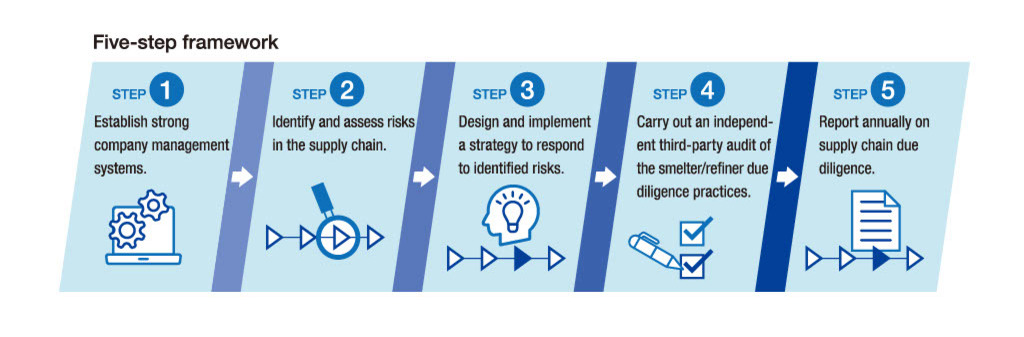

The five-step framework and Epson's initiatives

Step 1: Establish strong company management systems.

Epson establishes a Group-wide policy, implements a supply chain due diligence program, concludes written agreements with suppliers, and establishes a grievance mechanism.

Step 2: Identify and assess risks in the supply chain.

Epson identifies and assesses risks in its supply chain by conducting surveys.

Step 3: Design and implement a strategy to respond to identified risks.

Epson reports the results of risk assessments to the management, establishes risk mitigation plans, and monitors the performance.

Step 4: Carry out an independent third-party due diligence audit at specific points within the supply chain.

Epson supports audits conducted by RMI using the Responsible Minerals Assurance Process (RMAP).

Step 5: Report on chain supply due diligence.

Epson discloses its due diligence status on the company's official website, in its annual integrated report, and in other media formats.

1.Establish strong company management systems (step 1 in the five-step framework).

(1) Policy

Epson recognizes that the responsible sourcing of minerals is an important societal issue that it should address. Principles of Corporate Behavior, our top-level corporate code of conduct, describes the values and principles that Epson expects all officers and employees to embrace and demonstrate based on the Management Philosophy. It calls for the creation of an investigative system as a matter of company policy. Principles of Corporate Behavior are periodically reviewed to reflect social expectations and other factors. Revisions are approved by resolution of the board of directors. We also set forth initiatives and set targets for "key sustainability themes". Policies and results are discussed and reported at meetings of the Management Strategy Council, a corporate management meeting that is attended by members of the board of directors.

| Principles of Corporate Behavior

Principle 5: Ensuring effective governance and compliance We institute effective corporate governance and internal controls, and we observe laws, regulations, and other rules and maintain the highest ethics in all activities. 5.7 We will establish a system to investigate the source of minerals used in our products and supply chain and will take actions to responsibly source minerals to avoid using any minerals that could be involved in human rights abuses, conflicts or environmental degradation. |

(2) Survey Program

The Epson Group Responsible Minerals Survey Standard was established as a procedure for investigating mineral sourcing. It applies and is being used across the entire Epson Group. This standard conforms with the Due Diligence Guidance for Responsible Supply Chains of Minerals from "Conflict-Affected and High-Risk Areas" issued by the Organization for Economic Co-operation and Development (OECD Due Diligence Guidance). The survey program covers all parts and materials remaining in Epson products. The surveys are conducted using the Conflict Minerals Reporting Template (CMRT_3TG) and the Extended Minerals Reporting Template (EMRT_for other minerals, including cobalt and mica), provided by the Responsible Minerals Initiative (RMI). They enable us to identify upstream smelters and refiners of conflict minerals (3TG and cobalt) with the cooperation of suppliers of parts and materials. We also check the country of origin by obtaining answers about the supply chain.

We ask our suppliers to source minerals only from conflict-free smelters/refiners (CFS) certified by RMI's Responsible Minerals Assurance Process (RMAP). If suppliers indicate that they are unable to determine whether the source smelter is a CFS, Epson tries to avoid or mitigate risk by asking them to do additional checking or to source minerals from a different supply chain.

Epson holds supplier conferences for CSR at our manufacturing sites around the world. We use these conferences as well as other opportunities to promote understanding of Epson policies, ask suppliers to improve survey accuracy, and share information about trends in response to conflict minerals. We also endeavor to educate suppliers about survey templates and foster understanding about the surveys. We work in partnership with suppliers to ensure the responsible sourcing of minerals.

(3) Agreements with Suppliers

We request our suppliers to support our responsible mineral sourcing policies and also to comply with the Epson Group Supplier Guidelines and the Epson Supplier Code of Conduct (RBA Code of Conduct). In addition, we require our direct material suppliers to provide us with a written pledge to observe the Epson Supplier Code of Conduct (RBA Code of Conduct) and to cooperate with our mineral surveys.

(4) Grievance Mechanism

We have implemented a supplier whistleblowing system that our business suppliers can use to report mineral-related risks.

2. Identify and assess risks within the supply chain (step 2 in the five-step framework).

(1) Risk identification and assessment

Epson conducts surveys using the reporting templates (CMRT and EMRT) provided by the Responsible Minerals Initiative (RMI). The surveys are conducted in accordance with the Epson Group Responsible Minerals Survey Standard, which is compliant with OECD Due Diligence Guidance. The CMRT and EMRT allow users to select one of three declaration scopes: (1) Company-wide, (2) Products, or (3) User-Defined. However, Epson asks that suppliers select Product and answer with respect to specific products that are delivered to Epson so that we can surely verify the smelters/refiners of the minerals included in parts and materials used in Epson products. We believe that conducting the survey in this way will enable us to identify where we should mitigate risk and will result in effective due diligence.

Epson uses the certification status of the Responsible Minerals Assurance Process (RMAP), an RMI program that verifies the absence of risks in smelters and refiners, along with risk information obtained from customers and data on companies subject to transaction restrictions in various countries, to assess risks.

(2) Survey Results

In 2024, Epson covered both 3TG and cobalt in its survey across all its business operations. We asked 1,041 suppliers to complete the 3TG survey and received 2,728 reporting forms from 1,037 of them (99.6%). We asked 939 suppliers to complete the cobalt survey and received 2,291 reporting forms from 930 of them (99.1%). We analyzed suppliers’ answers and provided them with individual feedback based on the results within about a month or two. Suppliers with identified risks were asked to submit a corrective action plan and mitigate those risks.

Examples of identified risks

- There are smelters/refiners that cannot be identified.

- There are smelters/refiners that have not been certified as conforming to RMAP (including smelters/refiners in high-risk areas).

3TG Survey Results

| FY2022 | FY2023 | FY2024 | |||||

|---|---|---|---|---|---|---|---|

| Total | Tin | Tantalum | Tungsten | Gold | |||

| Number of identified smelters/refiners | 349 | 357 | 386 | 95 | 46 | 58 | 183 |

| Number of certified conformant smelters/refiners1 | 229 | 234 | 243 | 74 | 40 | 37 | 92 |

| Number active smelters/refiners2 | 16 | 5 | 4 | 1 | 0 | 1 | 2 |

|

Supplier response rate |

99% |

100% |

99.6% |

- | - | - | - |

1 Smelters and refiners certified as being Conformant under RMI's Responsible Minerals Assurance Process (RMAP).

2 Smelters and refiners certified as being Active under RMI's Responsible Minerals Assurance Process (RMAP).

* For detailed product-specific information, please contact your local Epson sales company.

Cobalt Survey Results

| FY2022 | FY2023 | FY2024 | |

|---|---|---|---|

| Number of identified smelters/refiners | 69 | 80 | 98 |

| Number of certified conformant smelters/refiners1 | 35 | 46 | 54 |

| Number active smelters/refiners2 | 7 | 4 | 8 |

|

Supplier response rate |

97% | 98% | 99.1% |

1 Smelters and refiners certified as being Conformant under RMI's Responsible Minerals Assurance Process (RMAP).

2 Smelters and refiners certified as being Active under RMI's Responsible Minerals Assurance Process (RMAP).

* For detailed product-specific information, please contact your local Epson sales company.

3TG survey results ( on products and procured parts basis)

As we aim for our products to be conflict-free and the information we provide to customers to be as accurate as possible, Epson also manages information on the basis of procured parts that are tied to products. By product, the results of the FY2024 survey confirmed that only RMI-certified smelters/refiners are used for products such as semiconductors*. Epson found that, by component category, around 30,000 of the approximately 58,000 parts and materials covered by the 3TG survey (roughly 50%) used minerals sourced exclusively from smelters/refiners certified by the RMI or classified as active.

* For information (name, country, etc.) on identified smelters/refiners associated with semiconductor products, see the "List of the Smelters or Refiners identified in Seiko Epson IC products supply chain which were known by RMI List of the Smelters or Refiners identified in Seiko Epson's supply chain which were known by RMI (PDF300KB)." For information (name, country, etc.) about identified smelters/refiners related to fine alloy powder, see the "List of the Smelters or Refiners identified in the Seiko Atmix supply chain which were known by RMI (PDF180KB)."

For detailed product-specific information, please contact your local Epson sales company.

3. Design and implement a strategy to respond to identified risks (step 3 in the five-step framework).

Epson mitigated risks by asking relevant suppliers to address risks identified by the surveys.

Risk management plan

- Explained and proposed possible risk mitigation measures to suppliers.

- Asked suppliers to submit a plan for addressing identified risks.

Tracking and monitoring of suppliers' risk mitigation efforts

- Meetings were held with individual suppliers to ascertain whether they have mitigated identified risks in their parts and supply chains.

- The results of surveys from suppliers who were asked to resubmit them were re-analyzed.

Concrete examples of risk mitigation

- We asked suppliers that were unable to identify smelters/refiners used for multiple minerals, including gold, to try again. After receiving their resubmitted data, Epson checked the smelters/refiners used in components delivered to it.

- A supplier of components using tin that was unable to verify whether some smelters/refiners were risk-free was asked to either undergo an RMAP audit or use a different source (or supply route). It was found as a result that those smelters/refiners were not used.

4. Information sharing and education for suppliers

Epson believes that responsible sourcing of minerals is an important societal issue that needs to be addressed, and since supplier understanding and cooperation are essential for achieving this, Epson strives to inform and educate its suppliers.

Throughout the year, we provide the following tools and information to ensure that suppliers always have up-to-date and easily accessible information:

- Excel Check Tool to check a smelter or refiner's RMAP certification information

- RMAP certification renewal information on smelters and refiners

In addition, we analyze the answers of suppliers who complete the surveys and provide them with detailed feedback on results, indicating what might have been missing and where improvements are needed. The feedback, which is issued on each reporting template, is intended to clearly indicate where a supplier needs to exercise due diligence.

We also explain the reporting templates and provide individual support for completing them in response to requests from suppliers.

We hold annual supplier conferences around the time we ask suppliers to complete the survey. At these conferences, we talk about responsible minerals sourcing, global trends in mineral issues, Epson's policies, and the OECD’s due diligence guidance. We also provide ongoing education on survey methodology and on how to answer survey questions. In 2024, a total of 1,047 individuals participated.

Since 2023, Epson has been conducting reviews to ensure that supplier's systems and initiatives for responsible mineral sourcing align with the OECD Due Diligence Guidance framework. Through these reviews, Epson examines suppliers’ survey policies, survey programs, and the processes used to provide answers on surveys submitted to Epson. When deficiencies or gaps are identified, Epson requests corrective action and provides support. With this type of communication with suppliers, we strive to strengthen their internal systems and improve their investigative capabilities.

5. Third-party audits

(1) Epson undergoes RBA Validated Assessment Program (VAP) audits at its manufacturing sites.

All sites that underwent a VAP audit between 2023 and 2024 were found to be in conformity with RBA's criteria for the responsible sourcing of minerals (D7 in the RBA Code of Conduct and E3 in the RBA VAP audit standard).

| Manufacturing Site | Country | Main Products Manufactured |

|---|---|---|

| PT. Indonesia Epson Industry | Indonesia | Printers |

| PT. Epson Batam | Indonesia | Printers |

| Epson Engineering (Shenzhen) Ltd. | China | Printers Projectors Robots |

| Epson Precision (Philippines), Inc. | Philippines | Printers Projectors |

| Epson Precision (Thailand) Ltd. | Thailand | Device Products |

| Epson Precision Suzhou Co., Ltd. | China | Device Products |

| Epson Precision Malaysia Sdn. Bhd. | Malaysia | Device Products |

* D7 in the RBA Code of Conduct: Responsible Sourcing of Minerals (Excerpt)

Participants shall adopt a policy and exercise due diligence on the source and chain of custody of the tantalum, tin, tungsten, gold, and cobalt in the products they manufacture to reasonably assure that they are sourced in a way consistent with the Organization for Economic Co-operation and Development (OECD) Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas or an equivalent and recognized due diligence framework.

See here for details on RBA audits.

(2) Epson had an independent, third-party auditing firm conduct a review of its systems and initiatives for the responsible sourcing of minerals to verify that Epson sources minerals responsibly in line with the OECD Due Diligence Guidance framework. The audit firm, in a written opinion following the review, stated that it had not found any discrepancy between Epson's efforts including the conflict minerals survey policy, the survey program and reporting, internal system development, or the implementation of the survey according to the plan and Epson's disclosure of the information on the efforts on Epson's website.

2024 Third Party Review Report on Responsible Mineral Sourcing (PDF,250KB)

2023 Third Party Review Report on Responsible Mineral Sourcing (PDF,150KB)

6. Partnerships with External Organizations

The conflict minerals problem is a global issue that we cannot solve alone. We, therefore, support and actively participate in the programs of the Responsible Minerals Initiative (RMI), which was established to address responsible mineral sourcing issues, and of JEITA, a domestic Japanese industry association. We also contribute to RMI's audit fund, believing that it is the responsibility of downstream companies to shoulder the costs of smelter and refiner audits.

Through alliance and group activities, Epson is working to resolve the issue of conflict minerals around the world and to improve conflict mineral investigation activities in the supply chain through industry collaboration.

Global initiative

Responsible Minerals Initiatives(RMI)

Number of member companies: 530+

Some of RMI's activities

・ Due diligence

・ Certification program

・ Development and provision of standardized reporting templates (survey forms)

Japanese industry associations

Japan Electronics and Information Technology Industries Association (JEITA) "Responsible Minerals Trade Working Group"

Domestic Japanese industry initiative

Japan Electronics and Information Technology Industries Association (JEITA) , Responsible Minerals Trade Working Group

Number of member companies: 50+

Some of the activities of JEITA

・Participating in the RMI and collaborating with international initiatives such as GeSI

・Monitoring and sharing information on the regulatory situation in various countries and regions

・Educating and raising awareness among suppliers

・Pressuring smelters that are not RMI-certified to undergo audits