Solving Social Issues Through Inkjet Technology

The SDGs, adopted around the globe, demand that we change the world to achieve a better and more sustainable future.

"We want to change the world with inkjet technology."

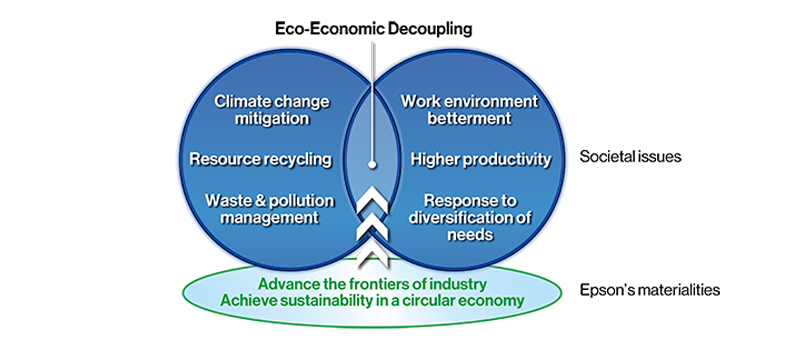

Propelled by this aspiration, we seek to transform methods and mentalities and to provide products, services, and production processes that have a far lower environmental impact on society, decoupling economic growth from environmental degradation.

This is Epson's mission.

Decoupling:

To separate economic growth from environmental impacts and the use of natural resources; and to increase resource and environmental

efficiency at every stage, from production to consumption to disposal, through technological innovation and social transformation.

Advantages of Inkjet Technology

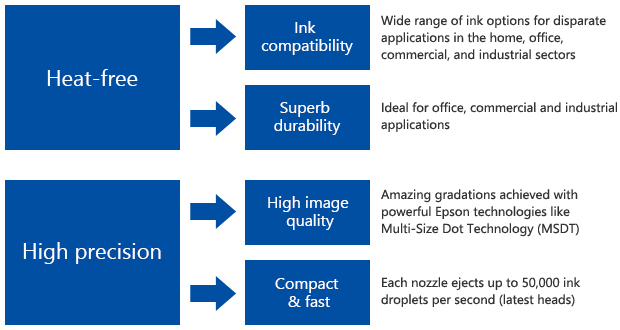

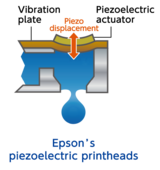

Epson's inkjet systems mechanically eject droplets of ink without heating it.

Since a non-contact method is used to deposit ink, Epson's inkjets can print on a wide range of media. And, because heat is not used, a variety of inks (substances) can be used.

Characteristics of Epson inkjet systems

Epson is deploying its state-of-the-art piezo-electric PrecisionCore printheads in printers across a wide range of categories.

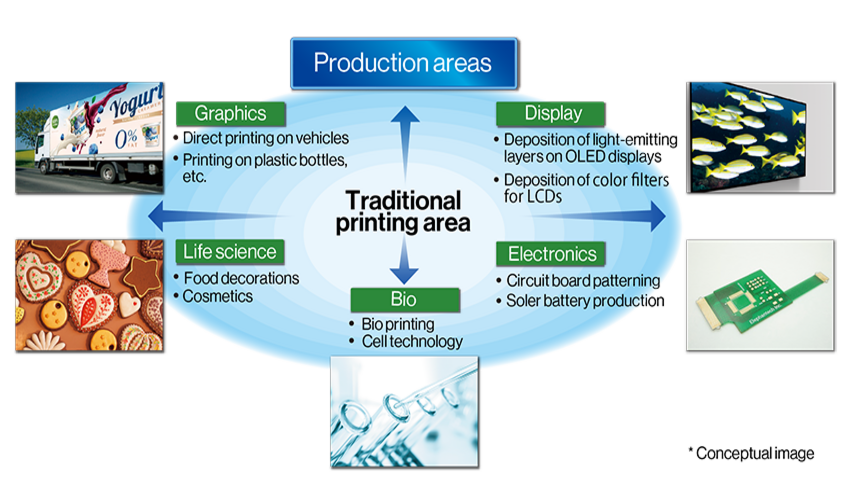

We want to use this technology, which can deliver value by boosting productivity while mitigating environmental impacts, to replace analog printing in every possible application. We are selling more printheads to external customers in response to the expansion of the digital printing market in the commercial and industrial sectors.

Future Outlook (Expansion in Production & Creative Areas)

Inkjet-based manufacturing innovations

Advancing the frontiers of industry through open innovation

We believe that a sustainable world is one where all people are happy and content and where the environmental impacts that society inflicts are dramatically lowered.

The time has come to promote the decoupling of economic growth from environmental impacts by innovating countless production processes with countless technological innovations. In other words, we must advance the frontiers of industry.

Epson's inkjet technology has the potential to satisfy the conditions for a sustainable world.

The number of potential applications for inkjet technology is growing.

To expand the use of this technology in new areas and to maximize its full capabilities, Epson needs to collaborate with outside partners who share our aspirations and who have new ideas and new technologies.

By combining our strengths with those of partners who have strengths in other fields, we can produce synergies and advance the frontiers of industry at a high level.

Further expanding inkjet applications through open innovation

TOPICS: Investment in Gosan Tech, a startup developing manufacturing equipment for perovskite solar cells using inkjet technology

Epson has invested in Gosan Tech Co., Ltd. (Gosan Tech), a South Korean startup with inkjet technology that can be used in a variety of industrial fields, including perovskite solar cells.

Perovskite solar cells are attracting attention as a next-generation renewable energy source and candidate to replace today’s silicon-based solar cells. They are lightweight, thin, and flexible, and the cost of fabricating them can potentially be reduced by utilizing production technologies such as inkjet printing. Moreover, significant improvements in power generation efficiency have been made in recent years thanks to active research and development.

As a partner, Epson will supply Gosan Tech with reliable and precise printheads suitable for industrial applications and will support Gosan Tech's business growth in cooperation with its sales and service site, Epson Korea Co. Ltd.

Epson will further promote the social implementation of inkjet technology through such initiatives.

State-of-the-Art Printheads

The evolution of Epson inkjet printheads.

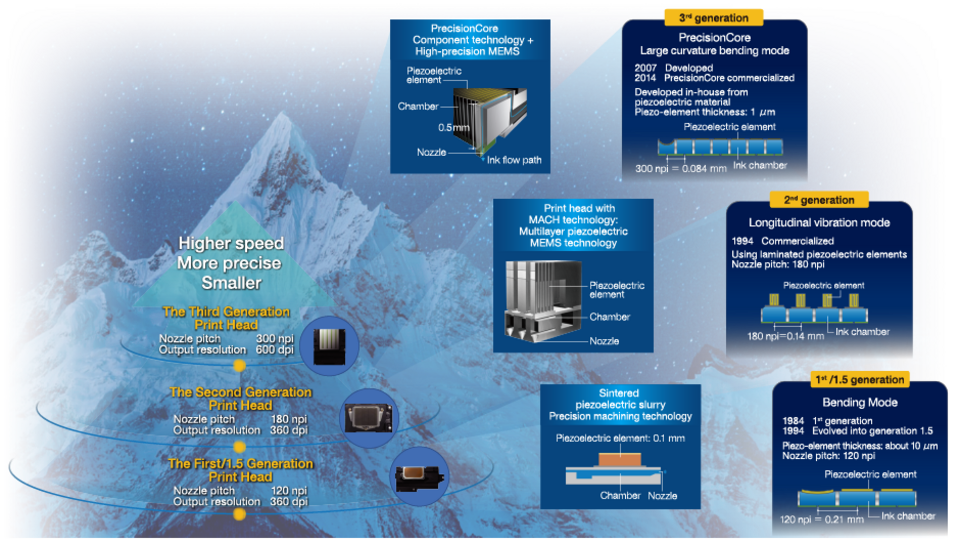

Epson's inkjet heads have evolved over three broad generations.

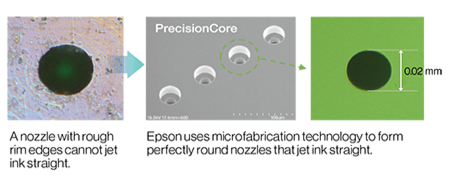

PrecisionCore head nozzles are 0.02 mm (20 µm) in diameter

That is about 1/5th the diameter of a typical human hair.

Piezo-electric inkjet heads consume little electricity and, since they are heat-free, are compatible with all manner of inks.

Since 1984 Epson's inkjet heads have evolved across three generations to become faster, more precise, and more compact.

PrecisionCore heads are the 3rd and newest generation. They were achieved by using the latest high-precision MEMS technology for everything from the ultra-thin film piezo-actuators to the nozzles.

Epson was able to obtain a larger displacement by fabricating thin-film piezo-actuators a mere 1 micrometer (1/1,000 mm) in thickness.

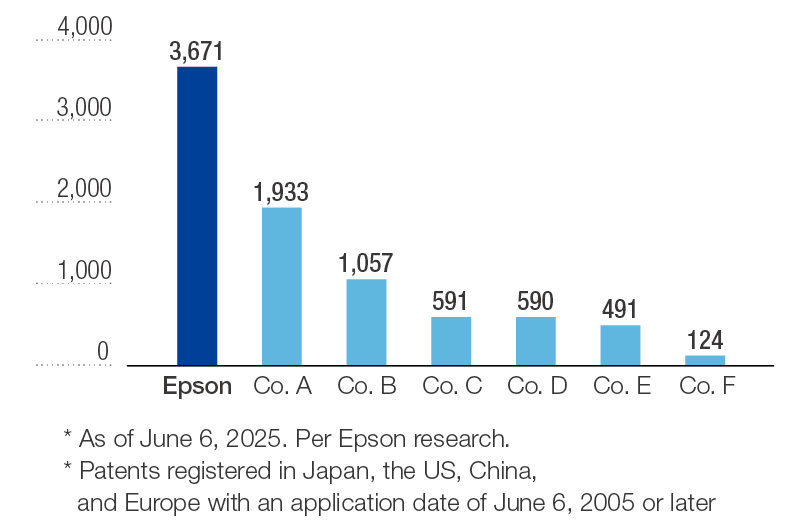

Key intellectual property

Epson owns a formidable number of piezo head patents around the world, and those technologies are incorporated into our heads.

Number of Piezo Printhead-Related Patents Owned

Business Growth and Low Environmental Impact

Operations launched in Building 9 at the Hirooka Office in 2018

Epson has laid a foundation for advancing the frontiers of industry by putting itself on a path toward tripling print chip production capacity and by acclerating external head sales.

Building 9 environmental considerations

- LED lighting throughout the building

The latest LEDs are also used for yellow lights for semiconductor fabrication. - High-efficiency air-conditioning system

Reduced the amount of construction materials and increased the efficiency of space use by using task and ambient air conditioning. - Low-carbon electricity used for production

All of the electricity needs of Hirooka office including Building 9 can be met with renewable energy.