Case study - Preservation of Water Resources

- Topic 1: Reducing Water Use by Improving Production Processes

- Topic 2: Preserving Water Resources and Reducing Organic Waste

Topic 1: Reducing Water Use by Improving Production Processes

PT. Epson Batam, which manufactures ink for inkjet printers and ink bottles for printers with high-capacity ink tanks, has been reducing its water use since 2018, chiefly by improving its production processes. In FY2021, it reduced the cubic volume of water used by approximately 6,800 tonnes compared to FY2017.

Improvement 1: Introduction of a cooling water circulation system (FY2018-2020)

A new cooling water circulation system, which consists of a cooling system, flow meter, temperature sensor, and other components, reduced the amount of cooling water used when reusing waste after ink bottles are formed.

Improvement 2: Utilization of distilled water produced in waste ink treatment (FY2021)

The introduction of a high-efficiency waste ink treatment system with an evaporation system produces a more condensed form of waste ink, reducing the amount of ink sludge that is recycled as industrial waste. The amount of distilled water produced when the waste liquid is condensed increased, and the distilled water is reused for lavatories, leading to a reduction in the amount of water used.

Conceptual illustration of waste ink treatment

by the waste ink treatment system (Improvement 2)

Topic 2: Preserving Water Resources and Reducing Organic Waste

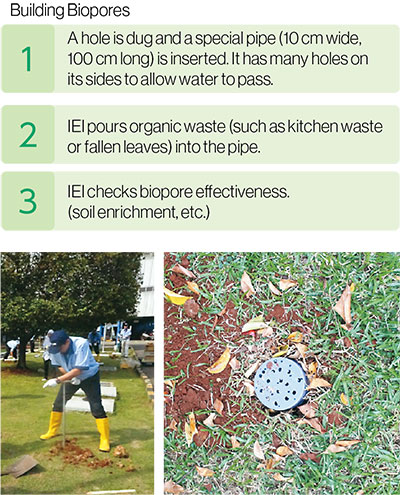

Jakarta, the capital of Indonesia, is struggling with land subsidence cause by flooding in the rainy season and groundwater shortages when it is dry. P.T. Indonesia Epson Industry (IEI), a large-scale printer production site, has introduced biopores, holes in the ground where rain can infiltrate. This solution has gained a lot of attention as something even households can do. In FY2018, IEI put biopores in 260 spots on its premises. These allow about 8,400 liters of rain to go into the ground every year. They also help prevent flooding and the pooling of water where mosquitoes breed. Additionally, fallen leaves and other organic waste can go into the biopores, which enabled IEI to reduce waste by 272 kg. The organic matter turns into compost, which enriches the soil.

IEI plans to continue installing biopores until it has them in 779 spots total, and to extend the initiative outside its premises.