Case Study - Reduction of Waste

- Topic 1: Recirculating & Reusing Cushioning Materials

- Topic 2: Reducing Waste Ink

- Topic 3: Making Printer Parts from Used Paper

- Other Case Studies

Topic 1: Recirculating and Reusing Cushioning Materials

Epson Service, which provides repair services for Epson brand products in Japan, has established a scheme to recycle and reuse cushioning materials that were previously disposed of as waste. Soft plastics such as bubble-wrap accounted for approximately 90% of the company’s CO₂ emissions from waste.

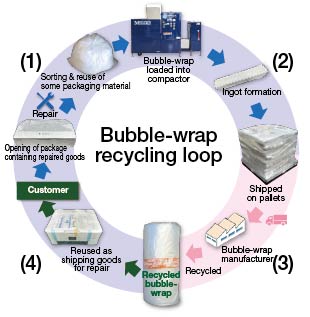

In this scheme, (1) packaging materials for incoming products are sorted and some are reused; (2) the bubble-wrap is compacted for efficient transportation and (3) delivered to the manufacturer as raw material; (4) recycled cushioning material is purchased and used when shipping repaired products back to customers.

This will reduce waste by 4.2 tonnes per year, reduce CO₂ emissions by 3.9 tonnes per year, and enable the continued use of bubble-wrap made from 80% or more recycled material.

Topic 2: Reducing Waste Ink

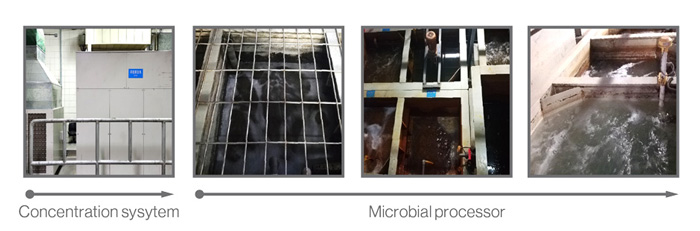

Epson Engineering (Shenzhen) Ltd., a printer production site in China, previously treated all waste ink from its printing inspection processes for printheads as industrial waste. The amount of waste and the high cost of treating it had become a challenge. The factory undertook to reduce waste ink by implementing a combined waste ink concentration system and microbial processor, a solution that was already in use in an Indonesian factory. As a result, about half the waste was restored to quality good enough it could be sent to the sewer and the other half could be recycled as concentrated liquid and sludge. That reduced waste ink by 481 tons per year and lowered yearly processing costs by about ¥30 million.

In addition, waste ink remaining after printing inspection is collected in a tank and gets a quality check (for foreign matter, viscosity, etc.), sent through filters, and reused.

| Liquid waste reduction (yearly) | Monetary value of benefit (yearly) | |

|---|---|---|

| Ink concentration | 481 t | ¥29,990,000 |

| Reuse | 56 t | ¥17,750,000 |

Topic 3: Making Printer Parts from Used Paper

Epson has established an internal paper resource cycle that uses paper used inside the company as a raw material. For example, we use our dry fiber technology to turn used paper into a raw material for functional recycled parts.

PT. Indonesia Epson Industry (IEI) is our largest printer manufacturing site. Some 12% of the waste created at IEI is paper used in printing inspection processes for printers. We have introduced dry fiber technology to take this used paper and reuse it as raw material for porous pads in printers. The result is a roughly 25% reduction in used paper waste (FY2016 results).

Porous pads, which absorb liquid like a sponge, are included in the maintenance boxes of business inkjet printers and large format printers to boost printer performance. Epson will continue to bring out the potential of paper resources as we develop and take advantage of new high-function parts that enhance product performance.