Design for Environment

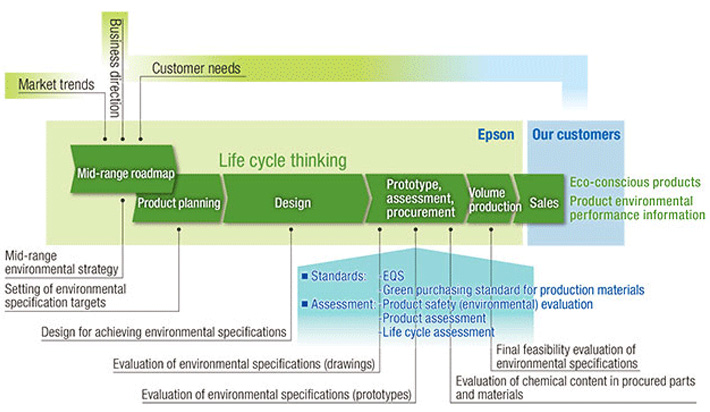

The environmental impacts of a product across its life cycle, from cradle to grave, are largely determined at the planning and design-engineering stages. Epson takes a life cycle thinkingapproach in efforts to minimize customers' environmental impacts by (1) providing products that change the way they work and live, and (2) providing products that offer environmental performance as a basic feature. We set concrete targets for environmental specifications that should be achieved at the product planning stage. And, we have introduced a design-for-environment (DfE) process in which we evaluate how well we did in and after the design stage.

Primary Environmental Performance Features

Below are some of the representative environmental performance features that we evaluate as part of our DfE process.

We explore various hardware and software approaches to save energy. These can include anything from developing energy-efficient technologies to implementing low-power product control systems. We strive to realize low-power products by setting and attaining concrete numeric targets several years out for each model.

Epson sets concrete size and weight targets for products, since reducing these helps to significantly mitigate environmental impacts, not only because fewer materials are consumed but also because products can be transported and warehoused more efficiently. We also make every effort to design products so as to minimize wastes on the customer's end. We do this by, for example, minimizing the amount of packaging used for products and consumables or by providing new printing functions that eliminate unnecessary prints.

We design our products to be easy to recycle after use. Specifically, we try to achieve a recyclable rate1 of 75% or better as estimated from product engineering drawings.

1 Recyclable rate: Recyclable materials as a percentage of total product weight, excluding materials used as reducing agents in blast furnaces or as fuel sources.

Epson standards specify substances that are prohibited from inclusion in products and substances whose inclusion must be controlled. Information on these substances is gathered in a database to help ensure safety in all processes, from design and procurement to volume production.

Design-for-Environment Framework

Epson prepares internal specifications, provides evaluation tools, and develops and commercializes products in line with work standards that set forth rules and procedures. The materialization of the environmental specifications is reviewed at each step of the product's commercialization before it is finally sold.

Eco-conscious Product Commercialization Flow (Example for the Printer Business)

Standards

・EQS (Epson Quality Standard)

Includes internal standards for safety and environmental requirements that all Epson Group products and parts must meet in their design, production and procurement

・Green purchasing standard for production materials

Basic opinion on "Product Chemical Content Guarantees," and written standards covering specific criteria and application, for use when purchasing production materials

Evaluation

・Product safety (environmental) evaluation

Compliance check

・Product assessment

Checklists and evaluation sheets for evaluating the feasibility of individual environmental specifications during the drawing stage and experimental manufacturing stage

・Life cycle assessment (LCA)

Tools for quantifying environmental impacts (global warming impacts) in a product's life cycle and for efficiently and accurately exposing areas whose design should be improved