Advanced Belt Technology

Advanced belt technology for high-speed printing

Inkjet printers are equipped with mechanisms for maintaining print quality. However, high-speed printing, which is essential for many offices and schools, requires advanced technology for quick maintenance. And this, in turn, requires internal mechanisms that move at high speed. Epson realizes this with unique high-speed, high-precision control technology.

Automatic printhead maintenance

Inkjet printers do not always use all their nozzles when printing. Without regular maintenance, the ink in the tips of infrequently used nozzles can dry out and cause cloggings, preventing the printer from providing the best print quality. The ink therefore needs to be periodically flushed from the print head to prevent the ink from drying out.

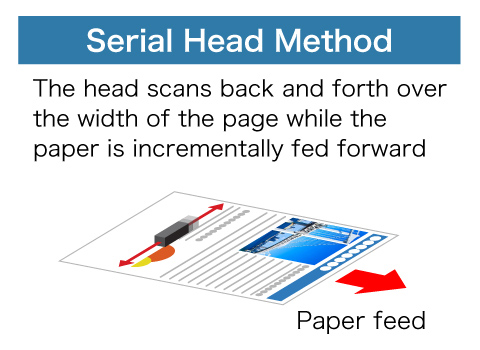

Serial head maintenance

In conventional serial head printers, the printhead scans rapidly back and forth over the paper while the paper is incrementally feed forwards. The printhead is moved into a maintenance area at this time to flush the nozzles.

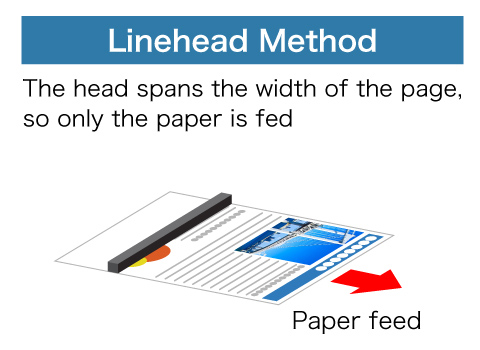

Maintenance issues with linehead

Linehead printers, on the other hand, have printheads that are the same width as the paper and remain stationary as the paper is fed forward, enabling lineheads to deliver higher print speeds.

In order to attain a speed of 100 pages per minute1, it is necessary to minimize the time spend in maintenance. When a printhead is moved for maintenance, it must be moved rapidly. Epson assumed that the mechanical shocks from sudden acceleration, deceleration, and stops would result in missing dots. For this reason, we needed a new maintenance method in which the maintenance unit would be moved at high speed instead of the printhead.

New maintenance method

Provided using YouTube™ services

YouTube is a trademark of Google Inc.

In the new maintenance method, an electrostatic belt is temporarily retracted during printing and a cap that protects the printhead during pauses instantly takes its place and absorbs flushed ink. The action that takes place during printing and flushing is illustrated in the video.

Maintenance in 1.65 seconds

Maintenance is performed in just 1.65 seconds to attain an output of 100 ppm. Parts such as the

electrostatic belt and cap must therefore be controlled with superb accuracy in a very short time. However,

the gap between the printhead and the electrostatic belt is only about 1 mm, so if you just try to move the

electrostatic belt quickly, the belt will collide with the print head, resulting in printer vibration, noise,

and mess. In addition, paper dust on the electrostatic belt gets raised and sticks to the surface of the

printhead, which can lead to clogged nozzles and missing dots.

Epson precisely controls the motor that moves the electrostatic belt, stops it exactly where it needs to be,

and completes maintenance in an extremely short period of time. Print quality is preserved even in continuous

high-speed printing thanks to this maintenance mechanism.

1: 100 pages per minute for single-sided landscape view printing on an LX-10000F series A4 printer.