Inertial measurement units (IMU)

Epson Inertial Measurement Units (IMU) Contribute to Sustainability

Modern society faces the problem of global food scarcity due to explosive population growth. The United Nations has defined "Zero Hunger" as one of its Sustainable Development Goals (SDGs). The theme of this goal is to end hunger, achieve food security and improved nutrition, and promote sustainable agriculture. Epson's inertial measurement units (IMU) are helping to meet these challenges.

Epson's IMUs help to address humanity's food problems

Solving humanity's food problems requires: (1) reducing consumption and loss, and/or (2) increasing production efficiency. One of the ways to increase production efficiency is to efficiently produce large quantities of agricultural produce through large-scale agriculture. However, numerous challenges lie in wait for those who would implement large scale agriculture. These include increasing machinery size, increasing costs, machinery operator workload, and an aging agricultural labor force. One idea for addressing these challenges is the concept of precision agriculture. One of the approaches this encompasses is the roboticization of agricultural machinery. This entails automating and increasing the size of tractors and other agricultural machinery used on large-scale farms, then using autopilot technology to operate them day and night. This would improve productivity by making work more efficient and reducing labor requirements. Epson's IMU technology can contribute to this large-scale agriculture.

Source: NovAtel, Inc

Implementing autopilot technology that surpasses the piloting accuracy of human operators

requires precise measurement of the machine's position, orientation and speed.

This necessitates GNSS/INS devices. A GNSS (Global Navigation Satellite System) is a satellite positioning

system that uses global positioning satellites to calculate the current location anywhere on Earth. The most

well-known example is the Global Positioning System (GPS). And an INS (Inertial Navigation System) is a device

that can determine its own position and speed using only built-in sensors, without support from external

signals.

Epson's high-precision IMUs are incorporated into both GNSS and INS devices, and are helping to improve the

accuracy of autopilot technology on agricultural machinery.

Such improvements to the performance of agricultural machinery are important not only in industrialized countries, but in developing countries as well. And to spur adoption of this technology, it is desirable to reduce machinery costs. Epson's high-precision IMU provides new value in terms of both performance and cost. Moreover, this kind of IMU-enabled automation technology is needed in a wide variety of fields from ICT construction machinery, to autonomous vehicles, and industrial robots. IMU technology can be employed from an ecological standpoint to reduce resource use and CO2 emissions through increased efficiency, and help to solve societal issues.

IMUs are indispensable

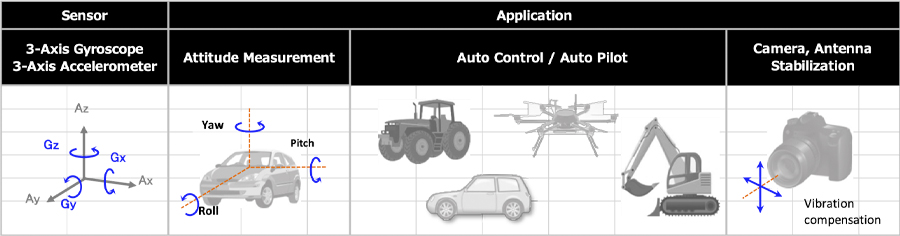

Because they can accurately measure the movement of objects in three dimensions, IMUs are essential to modern society. They are utilized in many more applications than just the aforementioned automatic control and autonomous driving on tractors and other agricultural machinery used for precision agriculture. Examples include orientation measurement during autonomous driving, drone orientation control, camera and antenna vibration detection and control, and controlling the angle and attitude of blades and arms on construction and mining equipment. The high-precision detection of tiny changes in movement, which are too small for the human eye to detect, makes IMUs vital to high-precision data measurement and control of machinery.

Epson's high-performance IMU achieves miniaturization and low power consumption

In this way, as demand has grown, IMUs developed for broad use in industry have gone on to be utilized in a variety of fields. In recent years, customers have sought IMUs with increased precision and stability, and ever greater miniaturization and low power consumption, that allow them to be easily incorporated into products.

IMU technology uses a combination of 3-axis gyro sensors to sense changes in rotation and direction, and 3-axis accelerometers to sense changes in speed along their axis. This technology can detect the amount of inertial momentum to a high degree of precision. Epson's IMUs use high-performance quartz sensor elements created by applying our original MEMS (microelectro-mechanical system) processing technology to high-quality crystal material that features excellent stability, low power consumption and low noise characteristics. Employing a crystal method allows devices to exhibit the characteristics of low noise, high stability and low variability. And their linearity characteristics enable high-precision measurement of various kinds of movement over a wide range from slow to fast. This allows them to be used in a broad array of applications.

Also, Epson has employed the SoC it developed specifically for industrial sensors based on the

compact, low power consumption IC technology we have built up over many years. This has allowed us to created

compact IMU products that greatly reduce peripheral equipment and power consumption, while maintaining high

performance.

In addition to compactness, light weight, and low power consumption, they are equipped with correction

functions to compensate for errors generated by things like vibration and temperature changes in actual usage

environments. They accurately detect even minuscule declination and movement, and consistently output

high-precision measurement data.

In this way, Epson IMUs are contributing toward the realization of a sustainable society in a variety of ways. And we foresee their application in a growing and even more diverse array of fields in the future. We aim for our IMUs to help spark innovation in customer products, and believe they will become essential to both our customers and to society.