Epson Engineers Win 2023 JSME Medal for New Technology

- Development of High Precision Vibration Sensors and Precise Lissajous Curve Drawing Methods -

- TOKYO, Japan, May 28, 2024 -

Three employees of Seiko Epson Corporation (TSE: 6724, "Epson") were recently awarded the 2023 Japan Society of Mechanical Engineers Medal for New Technology for the development of high precision vibration sensors and precise Lissajous curve drawing methods.

The Japan Society of Mechanical Engineers (JSME) commemorated the 60th year of its founding by creating an awards program in 1958 "to advance science and technology, and thereby contribute to the development of industries." Awards are presented annually in recognition of the best new technologies and papers. The JSME Medal for New Technology is awarded for technologies completed within recent years in the machinery industry. The medal is presented for the creation of technologies recognized for excellence in an evaluation that considers things such as originality, novelty, comparative excellence in quality or performance, and contributions to the economy or society through improved productivity.

JSME Medal Summary

The JSME Medal for New Technology

- Winning technology:

Development of High Precision Vibration Sensors and Precise Lissajous Curve Drawing Methods - Medal recipients:

Kenta Sato

Seiko Epson Corporation

Masayoshi Todorokihara

Seiko Epson Corporation

Masayuki Oto

Seiko Epson Corporation

Toshio Takiya

Hitachi Zosen Corporation

Takaharu Kitamura

Hitachi Zosen Corporation

Main reasons for selection

In recent years, there has been a growing interest in machine condition diagnosis technique (MCDT), a technology used to monitor, quantitatively assess, and diagnose faults in machines and other equipment. Interest has been spurred by increasingly severe labor shortages, as well as the need to extend the service lives of large machines used in social infrastructure by ensuring that periodic maintenance is performed as needed and the need to accurately determine when machine replacement is required.

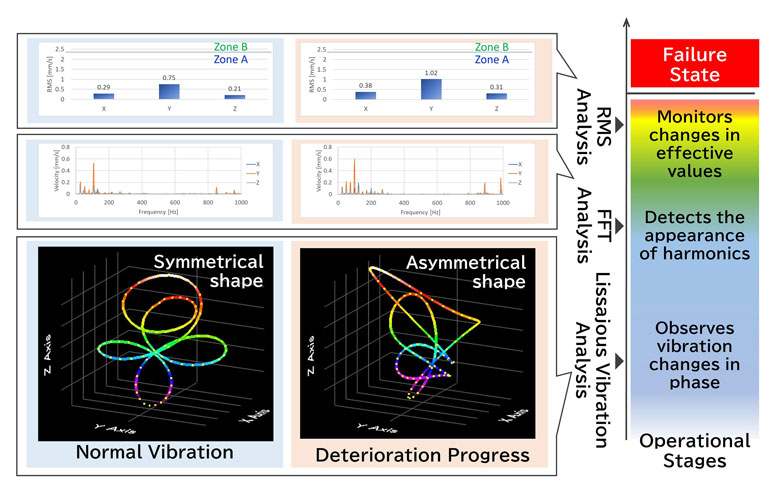

Conventionally, machine faults are diagnosed by monitoring changes in vibration intensity over time and analyzing vibration frequencies and peak values. However, given the growing interest in MCDT, an additional technique was developed that precisely visualizes the state of vibration using vibration phase information, which was previously not used.

The new technique earned high praise for enabling the observation and analysis of machine vibrations with precise 3D Lissajous curves owing to the integrated development of both hardware and software in the form of high-precision 3-axis synchronization and data processing algorithms.

The following are examples of what this technique can achieve and how it can be used.

What it can achieve

The combination of an Epson 3-axis vibration sensor and data processing reduce noise to greatly facilitates 3-axis vibration sensor installation and makes it possible to easily visualize changes in vibration symmetry, which was previously difficult with signal processing in the time and frequency domains.

Application examples

Large motors for opening/closing flood-control weirs, sluice gates, and dam gates

Epson will continue to facilitate its customers' equipment maintenance and vibration analysis by using this award-winning technique to detect machinery changes early by monitoring vibration phase changes and by analyzing in detail the causes of changes in condition based on low-frequency vibration shapes.

About Epson

Epson is a global technology leader whose philosophy of efficient, compact and precise innovation enriches lives and helps create a better world. The company is focused on solving societal issues through innovations in home and office printing, commercial and industrial printing, manufacturing, visual and lifestyle. Epson's goal is to become carbon negative and eliminate use of exhaustible underground resources such as oil and metal by 2050.

Led by the Japan-based Seiko Epson Corporation, the worldwide Epson Group generates annual sales of more than JPY 1 trillion.

corporate.epson/en/