Epson Atmix to Construct a New Production Facility at Kita-Inter Plant No. 2

- The new facility will boost production capacity of amorphous alloy powders1 to meet long-term demand -

- TOKYO, Japan, January 29, 2026 -

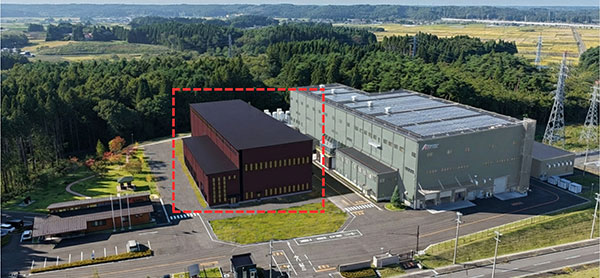

Epson Atmix Corporation ("Atmix"), a group company of Seiko Epson Corporation (TSE: 6724, "Epson"), will invest approximately 4 billion yen in buildings and production equipment to construct a new amorphous alloy powder production facility at Kita-Inter Plant No. 2, to meet growing market demand for applications such as AI and data centers.

The new plant is scheduled to start construction in September 2026 and begin operations in January 2028. Once operational, the facility will increase production capacity of amorphous alloy powders from approximately 6,000 tonnes per year to about 8,000 tonnes per year by fiscal 2028. Atmix already produces metal powders at its headquarters and at the Kita-Inter Plant. The addition of this third facility will help to ensure stable supply and enhance business continuity planning (BCP).

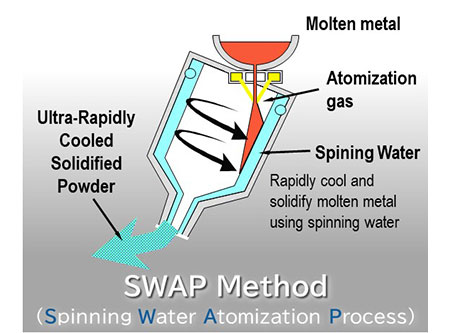

Atmix manufactures and sells fine alloy powders, including amorphous alloy powders, used as raw materials for various high-performance components in applications such as automobiles, smartphones, tablets, wearable devices, and medical equipment. In 2004, Atmix became the world's first2 company to successfully mass-produce amorphous alloy powders, a feat it achieved by using its proprietary SWAP® (spinning water atomization process)3 technology. These powders are prized for their outstanding high-frequency characteristics, high magnetic flux density, and low energy loss. These features enable improved performance in voltage control components, including reduced power consumption, miniaturization, and support for high-frequency and high-current applications. Demand for these powders continues to grow annually across industries such as smartphones, wearable devices, automotive, and energy-saving sectors. This trend is expected to persist over years to come.

Using raw materials produced at a metal refining plant completed in June 2025 at Kita-Inter Plant No. 2, Atmix will have in place a production network for amorphous alloy powders to ensure a stable supply of high-quality products and help enable compact, next-generation devices that save energy.

Atmix remains committed to leveraging its proprietary metal powder manufacturing technologies to provide high-quality products and services that customers can trust.

Profile of the New Production Facility at Kita-Inter Plant No. 2

| Location | 4-3-28 Kita-Inter Industrial Park, Hachinohe, Aomori, Japan |

|---|---|

| Products | Superfine alloy powders (amorphous alloy powders) |

| Building area | 2,188 m² |

| Total floor area | 3,085 m² |

| Start of construction | September 2026 |

| Start of operations | January 2028 |

Kita-Inter Plant No. 2, completed in June 2025, is Atmix's third production site. It serves as a metal refining plant that recycles unused metals into raw materials for Atmix's metal powder products. Atmix continues to strengthen and expand its production organization as needed to ensure a stable supply of products for customers today and in the future.

Related Links:

Epson Atmix Launches Operations at New Plant for Recycling Used Metal(June 6, 2025)

URL:corporate.epson/en/news/2025/250606.html

Epson Atmix Profile

| Name | Epson Atmix Corporation |

|---|---|

| Established | October 1, 1999 |

| Address |

Headquarters 4-44 Kaigan Kawaragi Hachinohe Aomori 039-1161 Japan Kita-Inter Plant 2-1-60 Kita Inter Kogyo Danchi Hachinohe Aomori 039-2245 Japan Kita-Inter Plant No. 2 4-3-28 Kita-Inter Industrial Park, Hachinohe, Aomori, Japan |

| President | Ryo Numasawa |

| Capital | 450,000,000 yen (Epson Atmix is a wholly owned subsidiary of Seiko Epson Corporation) |

| Employees | 432 (as of April 2025) |

| Business | Development, manufacture, and sales of metal alloy powders, metal injection molded parts, and synthetic quartz crystals |

About Atmix

https://www.atmix.co.jp/en/index.html

-

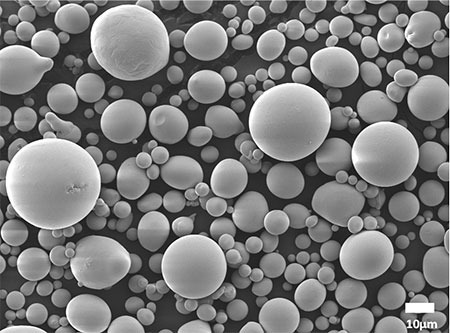

1 Amorphous alloy powder

Ordinary alloys have a crystal structure in which atoms are regularly arranged. Amorphous alloys, on the other hand, are made up of atoms that have an irregular arrangement, so although they are solid, they are similar to liquids in that they have densely packed atoms arranged in an irregular structure. Made up of granules with diameters ranging from several dozen to several hundreds of microns, amorphous alloy powder is lightweight and has excellent energy conductivity and strength. - 2 per Epson Atmix research

-

3 Spinning water atomization process (SWAP)

SWAP is Epson Atmix's proprietary alloy powder production method that enables mass

production of amorphous alloys. Alloys melted in a high-frequency induction furnace are atomized by gas and subjected to ultra-rapid cooling at several hundred thousand degrees Celsius per second by a high-speed spinning water stream to produce alloy powder in an amorphous state. - Note: SWAP is a trademark of Epson Atmix Corporation.

About Epson

Epson is a global technology leader whose philosophy of efficient, compact and precise innovation enriches lives and helps create a better world. The company is focused on solving societal issues through innovations in home and office printing, commercial and industrial printing, manufacturing, visual and lifestyle. Epson's goal is to become carbon negative and eliminate use of exhaustible underground resources such as oil and metal by 2050.

Led by the Japan-based Seiko Epson Corporation, the worldwide Epson Group generates annual sales of more than JPY 1 trillion.

corporate.epson/en/