Epson and Epson Atmix Awarded the Prize of the Minister of Education, Culture, Sports, Science and Technology at the 2024 Tohoku Regional Commendation for Invention

- The invention of amorphous soft magnetic alloy powder contributes to smaller, thinner magnetic components and lower power consumption -

- TOKYO, Japan, November 7, 2024 -

Seiko Epson Corporation (TSE: 6724, "Epson") and Epson Group company Epson Atmix Corporation are pleased to announce that they have received the Prize of the Minister of Education, Culture, Sports, Science and Technology, the highest award in the regional commendations for invention, for the invention of amorphous soft magnetic alloy powder (Patent No. 6123336) at the 2024 Tohoku Regional Commendation for Invention sponsored by the Japan Institute of Invention and Innovation. This is the first time that Epson Group has received an award in the Tohoku Regional Commendation for Invention. This is also the fifth time that the Epson Group has received this award at the Regional Commendation for Invention.

The award ceremony was held on November 6 at Wedding Plaza Alaska, in Aomori City.

The Regional Commendation for Invention, which began in 1921, divides the nation into eight regions (Hokkaido, Tohoku, Kanto, Chubu, Kinki, Chugoku, Shikoku, and Kyushu) and honors engineers and research developers who have created outstanding inventions, utility models, or designs in their respective regions.

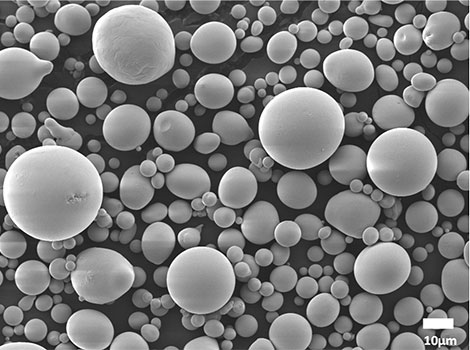

The invention that was awarded the Prize is related to an amorphous soft magnetic alloy powder with iron as the main component. The powder's coercivity, average particle size, and tap density were optimized to achieve both high saturation magnetic flux density1 and low iron loss (low hysteresis loss and eddy current loss)2 in magnetic components with a core formed from this alloy powder.

Magnetic components using this invention have become indispensable for reducing power consumption and making electrical circuits smaller and thinner in high-performance electronic devices such as mobile phones and electric vehicles that require high-frequency and/or high-current control. They thus help to reduce environmental impact.

Prizes and winners

Prize of the Minister of Education, Culture, Sports, Science and Technology

| Hiroyoshi Otaka | Metal Powder Production Engineering Section, Metal Powder Production Department #1, Epson Atmix Corporation |

Prize for Invention Implementation Achievement

| Yasunori Ogawa | President and Representative Director, Chief Executive Officer, Seiko Epson Corporation |

| Isamu Otsuka | President and Representative Director, Epson Atmix Corporation |

About Epson Atmix Amorphous Soft Magnetic Alloy Powder

In 2004, Epson Atmix became the first company in the world to successfully mass-produce amorphous soft magnetic alloy powders, which are used as raw materials for various high-performance components in automobiles, smartphones, wearable devices, medical equipment, and more, using its proprietary SWAP (spinning water atomization process)3 method.

The demand for amorphous alloy powders has been rising year after year. Unlike ordinary alloys, which have a crystalline structure where atoms are arranged in a highly ordered pattern, the atoms in amorphous alloys have an irregular structure. This structure gives amorphous alloys high magnetic flux density and low energy loss in addition to excellent high-frequency characteristics. These characteristics make amorphous alloy powders valuable as a high-performance material that improves the performance of voltage control components in terms of low power consumption, miniaturization, high frequency, and high current.

For further information, please visit the Epson Atmix web site at:

http://www.atmix.co.jp/en/index.html

- 1 High saturation magnetic flux density

The magnetic flux density (amount of magnetic flux per unit area) is high when a magnetic material becomes magnetically saturated. Since a large amount of magnetic energy can be stored, it is possible to realize higher current and smaller components, which enhances their conversion efficiency and durability. - 2 Low iron loss (low hysteresis loss and eddy current loss)

hysteresis loss: The electrical energy loss in the coils with magnetic material cores, which are found in components such as inductors and transformers, that occurs when the magnetic domains in the core change direction of magnetic fields due to alternating current (AC).

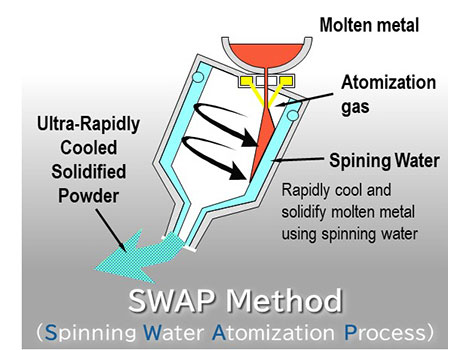

Eddy current loss: Loss caused by eddy currents in the iron core. The higher the frequency, the greater the ratio of eddy current loss. - 3 Spinning water atomization process (SWAP)

SWAP is Epson Atmix's proprietary alloy powder production method that enables mass production of amorphous alloys. Alloys melted in a high-frequency induction furnace are atomized by gas and subjected to ultra-rapid cooling at several hundred thousand degrees Celsius per second by a high-speed spinning water stream to produce alloy powder in an amorphous state.

Note: SWAP is a trademark of Epson Atmix Corporation.

About Epson

Epson is a global technology leader whose philosophy of efficient, compact and precise innovation enriches lives and helps create a better world. The company is focused on solving societal issues through innovations in home and office printing, commercial and industrial printing, manufacturing, visual and lifestyle. Epson's goal is to become carbon negative and eliminate use of exhaustible underground resources such as oil and metal by 2050.

Led by the Japan-based Seiko Epson Corporation, the worldwide Epson Group generates annual sales of more than JPY 1 trillion.

corporate.epson/en/