The future of fashion co-created with YUIMA NAKAZATO

On July 9, 2025, Epson supported YUIMA NAKAZATO’s latest collection, "GLACIER," which was shown at Paris Haute Couture Week Autumn-Winter 2025-2026.

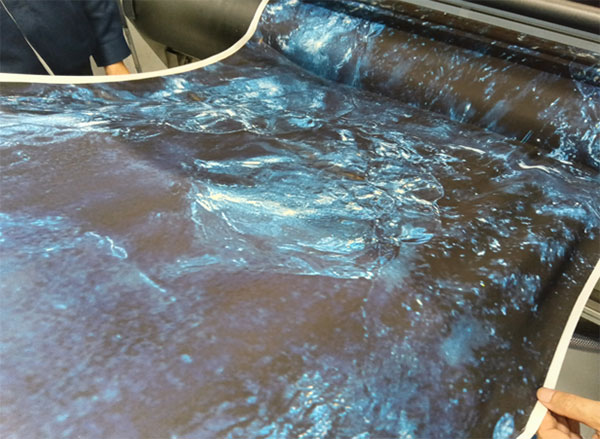

For this season’s collection, Mr. Nakazato traveled through Lapland in Finland, searching for the origins and true purpose of clothing. Inspired by the extreme conditions of the Arctic, the collection explores human vulnerability and the roles that garments play. Photographs taken by Mr. Nakazato of Lapland’s stark landscapes were reproduced on fabric using Epson’s digital textile printing technology, and footwear was crafted in part from non‑woven fabric sheets made with Dry Fiber Technology*1, that were recycled from used garments, yielding new forms and encapsulating surface effects that depict the aurora borealis.

Double-sided printing with the ML-16000JQ expands fashion’s possibilities

To achieve a sense of unity through movement, the couture house used deep slits at hems and sleeves and incorporated double-sided printing so that motifs were revealed from both sides as the fabric turned. This was made possible by Epson’s ML-16000JQ printer, which prints identical designs on both sides of fabric with precise alignment.

The ML‑16000JQ includes a camera unit for exact pattern matching between front and back and can recognize fabric patterns in real time, enabling high‑precision printing on jacquard, embroidery, and woven lace. The result is continuous imagery that shifts with the cloth, while removing linings lightens the garments and enhances the minimalist silhouettes.

"Normally, when printing on the surface, the reverse stays white. So, until now, I had to line garments and double the fabric, which was more costly," Mr. Nakazato explains. "Now I can print the same artwork on both sides and expand artistic horizons."

©Gio Staiano

Digital printing broadens material expression

The GLACIER collection comprises 26 looks - including dresses, trousers, jackets - each enhanced by digital textile printing to maximize color, texture, and drapery. Alongside silk organdy, prints appear on a wool blend of Brewed Protein™ fibers and cashmere, achieving a refined, silky touch.

Non-woven fabric sheets and urushi lacquer: Japanese traditional craft meets sustainability

As in previous collections, Epson once again supported garment production through its Dry Fiber Technology. Previously used for sneakers, non-woven fabric sheets are now applied to a wider range of footwear and dresses. Dry Fiber Technology can defibrate blended fabrics made from multiple fiber types using very little water, enabling reuse of offcuts and discarded garments.

For GLACIER, non‑woven fabric sheets made from fiberized sewing offcuts and used garments (collected by Mr. Nakazato during an earlier visit to Kenya) were incorporated into designs. Mr. Nakazato notes that the sheets’ texture recalls traditional Japanese ink painting and washi paper. To deepen that reference and to evoke the aurora, he applied urushi lacquer to sheet surfaces, producing a subtle shimmer. The result is a cohesive interplay of material, color, and texture across footwear and garment details, giving the recycled sheets a renewed aesthetic value.

©Gio Staiano

1 Proprietary Epson technology for defibrating a wide variety of materials for functional, high-performance applications with very little water. For details, please click on the link to the Dry Fiber Technology website. Dry Fiber Technology